Applying automation lessons from manufacturing in the lab

How the lessons we learned from manufacturing automation can help supercharge your lab’s throughput

Despite the improvements to throughput, quality and staff utilisation that lab automation can bring to lab environments, it is still being under-utilised. Yet, in manufacturing, end-to-end automation has revolutionised entire industries.

The idea that open, integrated automation can revolutionise processes at an enterprise level is far from new. On factory floors around the world, humans and robots are working side by side every day.

Our background in automating manufacturing processes has shown us how the wide-scale adoption of automation can truly transform the production of automotives, metal works and electronics – all at the click of a button by a human operator.

In these highly automated spaces, the experience of scientists and engineers is used very purposefully on complex tasks, leaving high-output applications, where possible, to automated systems.

However, where car manufacturers are about consistency and predictability – most will know what they’re building for the next five years – labs are about discovery and change. This is why many in the life sciences industry have hesitated to borrow such rigid production techniques. But now a range of providers like Automata are delivering a new approach that combines the repeatability, scale, quality, throughput, and efficiency enjoyed by factories, but with the flexibility and adaptability demanded by labs at the cutting edge.

The insights we’ve gained can improve labs’ results, increase efficiency, and free scientists from repetitive tasks, revolutionising how they work and innovate today. Here’s what we’ve learned from the manufacturing industry.

Lesson 1: Optimising bottlenecks

There’s a simple rule of thumb within the manufacturing space: it’s critical you get maximum utilisation out of your most expensive piece of equipment. In a lab this is often a liquid handler, which can cost hundreds of thousands of pounds. The closer you can get to 100% utilisation of these pieces of equipment, the more efficient your lab will be.

However, these instruments are often left unused for hours or even days at a time while they wait for the completion of other lengthy manual processes such as sample preparation, DNA extraction, centrifuging and moving samples in and out of a liquid handler. By investing in the efficiency of those processes, labs can reduce waiting and get more value from their flagship devices.

We went into one lab where a liquid handler sat idle for 3.5 hours out of a six-hour library prep process while thermocyclers ran. Simply adding more thermocyclers sped up the process enough to double the liquid handler’s output in the same time – proof that getting a harmonious mix of equipment in the lab can deliver enormous benefits.

Lesson 2: Parallelising processes

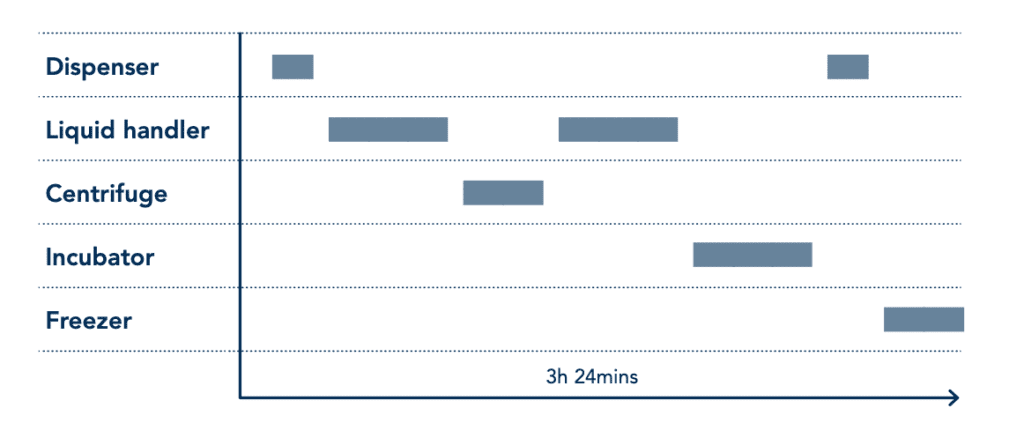

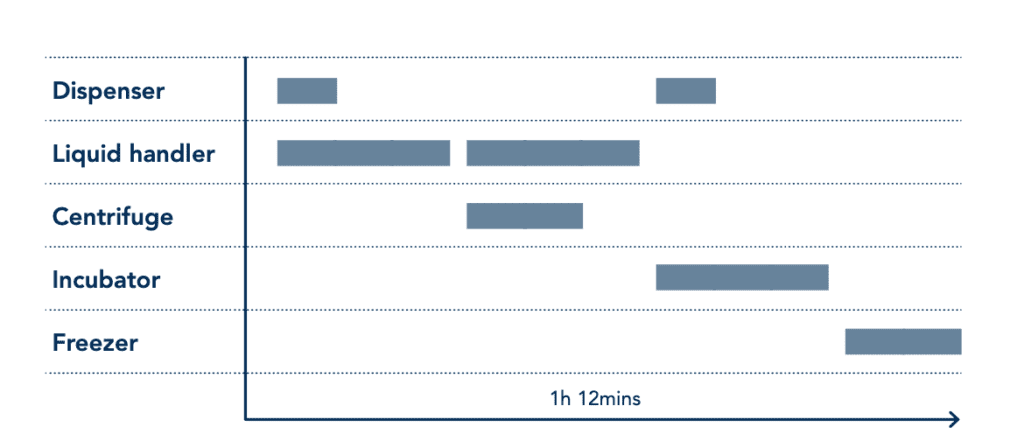

On a factory floor, manufacturing steps are decoupled so that formulation, blending, packing and cleaning all take place simultaneously. Processes run independently; no step relies on the completion of another, so efficiency is maximised.

Labs sometimes fail to reap the same rewards as devices like liquid handlers often have multiple functions ‘on deck’ that work in a linear manner. What was intended to provide more walkaway time often creates an unintended bottleneck as staff wait for an uninterruptible process to finish before moving on to the next step.

Instead, labs should break down SOPs into units of operations – decoupling steps such as pipetting or thermocycling – so that these can all be parallelised on different pieces of equipment. An open, integrated approach to automation such as the one that Automata brings to labs we partner with can help labs identify these units.

Lesson 3: Harnessing the power of robotic and digital connections

In an automotive factory, equipment connects all the processes on the assembly line so that the car autonomously moves through different instruments for processes such as attaching parts or spray painting. Yet in a lab, humans still provide these connections.

Think bigger with automation

Manufacturing insights have taught us that automation isn’t just about investing in one piece of equipment. It’s about thinking beyond individual instruments. Labs can transition from a series of modular, semi-manual processes to a fully automated end-to-end workflow.

Moreover, we believe labs can use insights from other industries beyond manufacturing to take the next steps on their journey to automation. Doing so has already helped us deliver demonstrable improvements to workflows so we now know that every lab stands to gain from automation.

Download the full whitepaper: ‘The journey to the fully automated lab of the future’ to learn more about how can use all these exciting new features to see meaningful improvements in how your lab works.