Increase throughput, traceability, and efficiency in a range of scientific methods

Boost the speed and efficiency of your lab with LINQ, automating key scientific methods while cutting down hands-on time for your scientists. Discover how our integrated solution overcomes the limits of bench-top automation, driving higher throughput and enhanced traceability across various applications.

Cell Biology

Unlocking scale in cell line development with automation

Unlock the potential of automation in cell line development (CLD) by generating and screening far more clones with greater data integrity, traceability, and high-throughput analysis—driving smarter decisions from complete, end-to-end workflows.

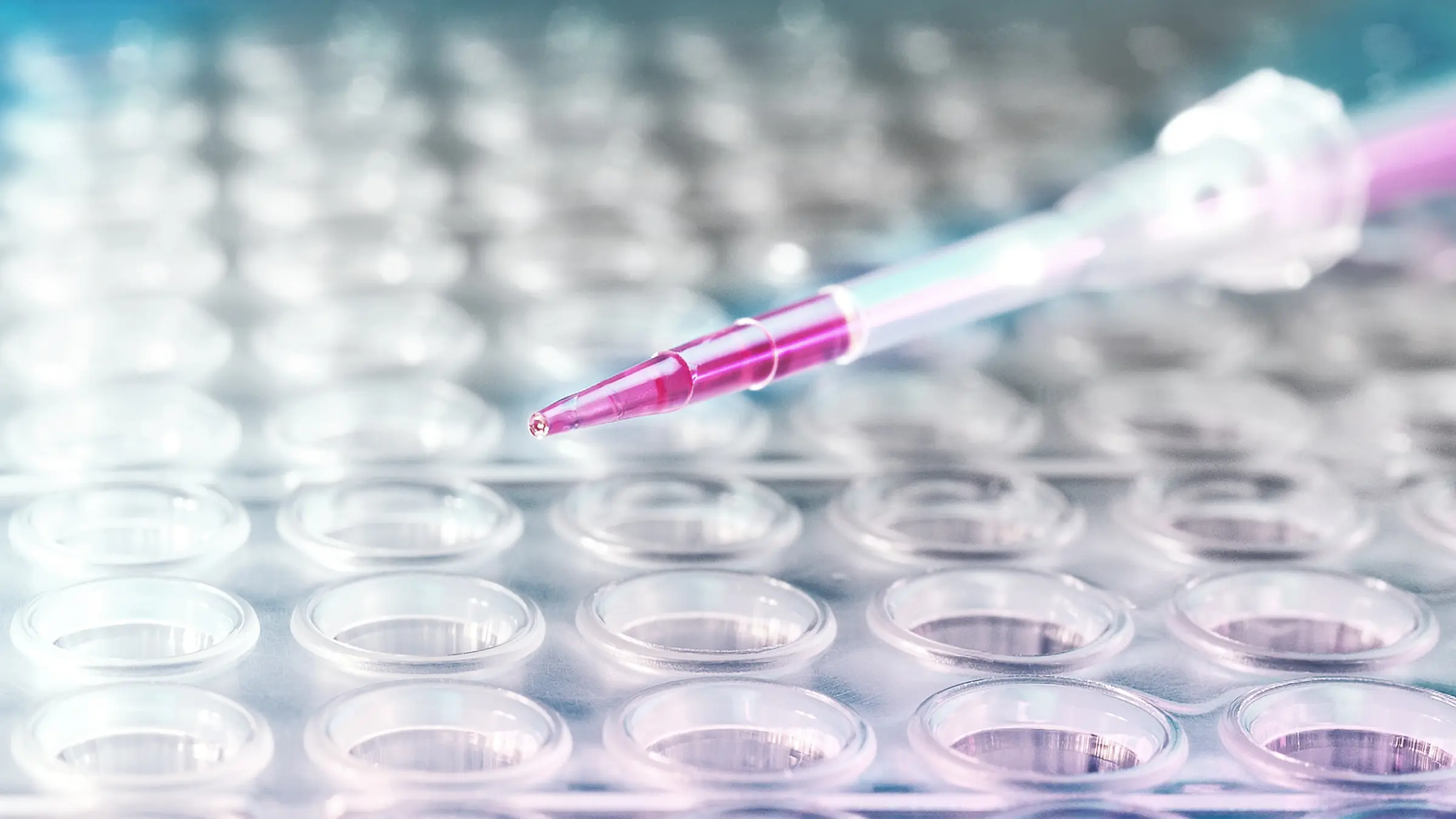

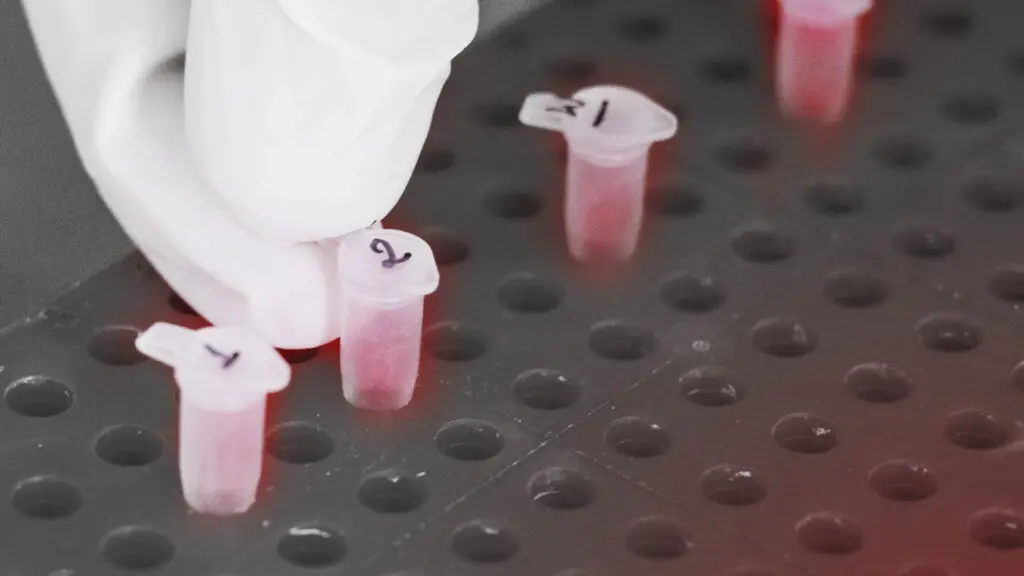

Automating media exchange in cell culture workflows

Free your scientists from manual tasks with open, integrated automation that boosts lab efficiency, extends operational time, and enhances cell culture processes.

The complete lab workflow automation platform for ipsc

Transform your iPSC workflows with LINQ—enhance reproducibility, scale throughput, and achieve true walkaway automation in your lab.

Genomics

address increased genomics testing demand in public healthcare

Increase genomics testing capacity with 3x throughput, 70% cost savings, and no need for high CAPEX or additional hires. Automate workflows for cancer panels, prenatal testing, and rare disease screenings.

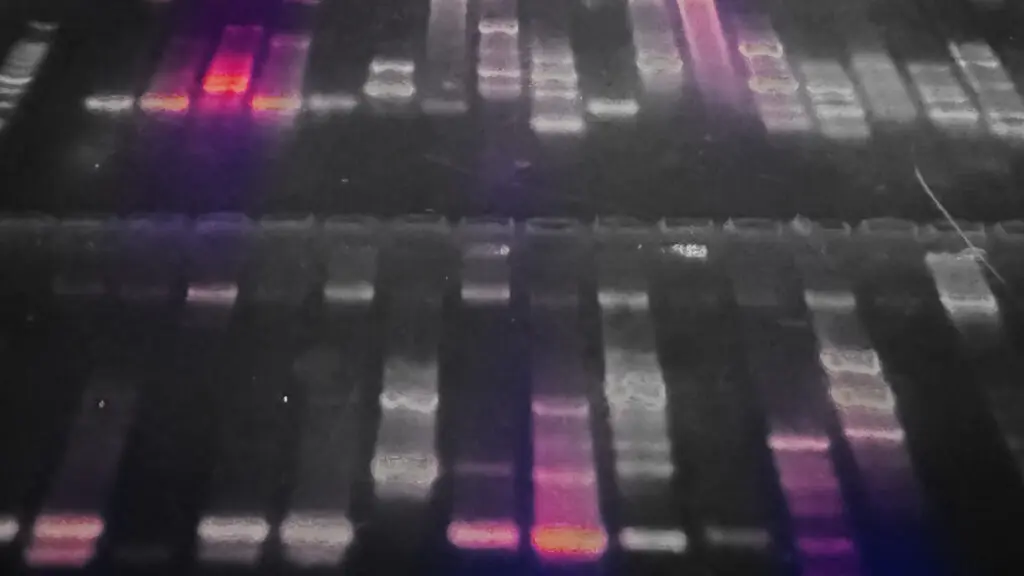

quality control (qc) in genomics workflows

Discover an example of LINQ reducing manual touchpoints from 1388 to 7, cutting setup time from over 6 hours to just 15 minutes—enabling true walkaway automation and eliminating tedious manual tasks in QC workflows.

automated nucleic acid extraction and quality control

Automate and scale nucleic acid extraction with LINQ—standardize workflows without needing more instruments or space, while giving scientists more time for analysis and reporting.

automating ngs library preparation

Automate NGS library preparation with LINQ—reduce manual touchpoints, double throughput, and free up your scientists’ time without adding extra staff or instruments.

Drug Discovery

truly hands-off elisa automation

Discover how our fully automated ELISA platform streamlines workflows, freeing your scientists from manual tasks with open, integrated automation that scales as your lab grows.

cell-based assay workcell

Explore our fully automated cell-based assay workcell—a scalable, sustainable system designed for complex compound testing with minimal consumable costs and full walkaway capabilities.

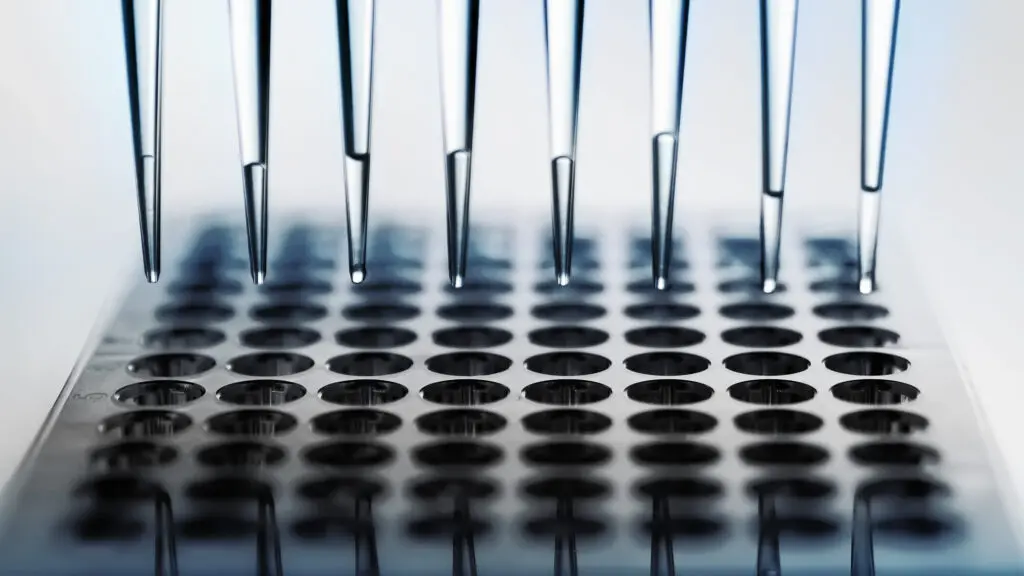

High throughput screening workcell

Discover our high-capacity, fully automated workcell for high throughput screening—run complex compound screens with multiple readouts, generating more data with minimal error rates.