The main lab automation benefits are reproducibility (quality), data accuracy, traceability, efficiency, safety, and faster translation from bench to bedside.

Reproducibility

Reproducibility has always been a major concern for laboratories. In 2011, a Nature survey highlighted the widespread challenge of reproducibility when it found that 70% of scientists have tried and failed to reproduce another’s experiments.

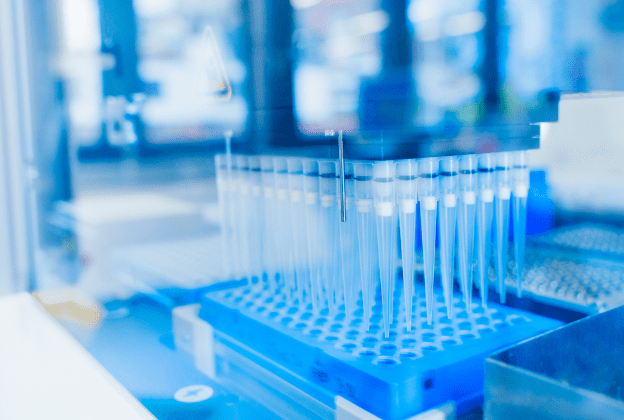

Automation has the potential to reduce handler-induced variability and contamination, resulting in improvements in quality of results.

In the research environment, for example, laboratory automation can enable a greater rate of experimental data capture, increased volume of results, and the use of a wider range of controls, increasing the likelihood that results will be reproducible. Reproducible data can then be built upon with further research.

Elsewhere, in clinical labs, automation can also reduce pre-analytic errors such as mislabelling or misplacing samples, or selecting the wrong media.

Data accuracy

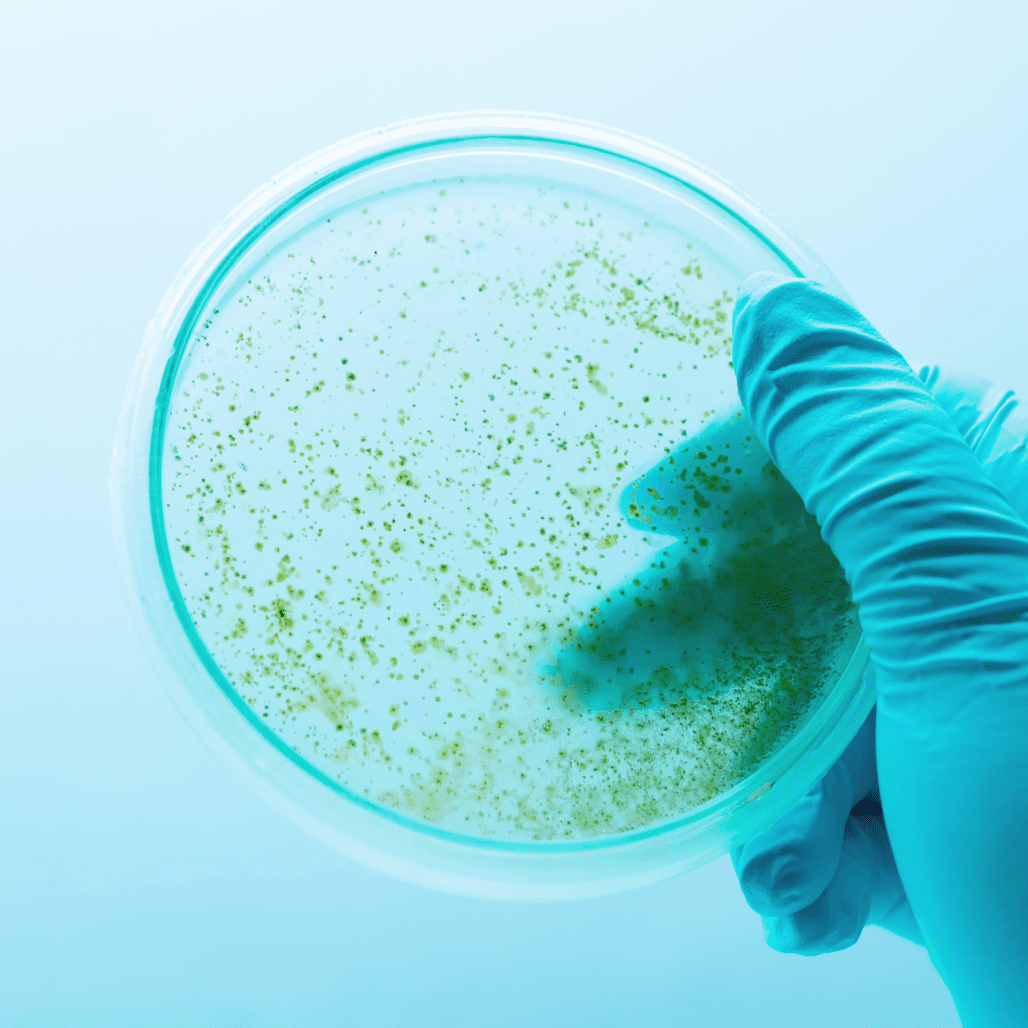

Data accuracy is one of the aspects of laboratories that can be improved with lab automation. In the microbiology lab, consistent automated plate streaking of urine samples allows for more accurate differentiation of a potential pathogen from contaminating microbiota, for instance.

Automated processes and tools can incorporate machine learning algorithms that improve the accuracy of data evaluation compared to human-based interpretation. They do this by avoiding idealised training subsets and learning from a larger pool of real samples. For example, automation of slide imaging and Gram stain interpretation can improve upon the manual classification of common bloodstream pathogens, and automated echocardiogram analysis can classify a range of pathologies with high levels of accuracy.

Traceability

Traceability is another significant benefit of lab automation.

The ability to compare test results to each other and to standards is critical both to academic research laboratories and clinical laboratories. Another important aspect of traceability is data provenance, the ability to describe the history and origins of data.

In the research lab, traceability is essential to enable the translation of findings to the clinic. In the clinical laboratory, on the other hand, the importance of this concept is highlighted by the inclusion of metrological traceability in the requirements for accreditation by ISO 15189:2012. In cases where clinical practice guidelines recommend medical action based on test results, traceability mitigates the risk of medical harm to a patient.

The challenges inherent in maintaining traceability in any life sciences laboratory can be eliminated with automation. Laboratory automation increases the capacity of the lab to process samples with adequate documentation and accuracy, and it can also take care of the chain of custody of data.