Industry insider: my takeaways from SmartLabs UK 2022

Integrating data from the offset and LEGO lab automation: Here’s what I picked up at this year’s SmartLabs UK

At this year’s SmartLabs, lab automation and the necessity of digital transformation were the hottest topics of discussion, with a focus on overcoming obstacles the technology presents for lab environments. Because while we can all agree that automation is the future, four decades after it first appeared in labs it is still only truly embedded in a minority of them.

With decades of experience building lab automation projects for some of the industry’s largest providers, here are my thoughts and takeaways from this year’s SmartLabs UK.

These are the challenges still preventing further adoption of lab automation

Limited laboratory space is a common theme in the industry today, and a concern raised by several SmartLabs speakers and attendees. Because while labs would ideally build in automation from the very beginning, this kind of setup is rare. This means that much of the big box automation that has been used in the past is too bulky to fit into existing labs. Often in these systems, everything tends to be crowded around the robot, which also takes up more space.

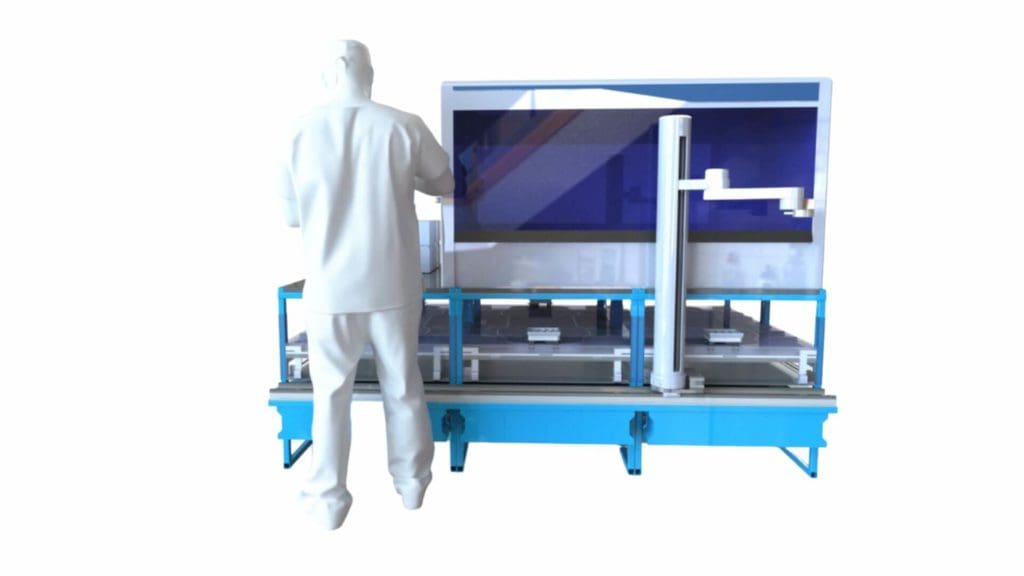

What’s more, another challenge is that these sorts of systems are intimidating and unapproachable. However, at the other end of the spectrum, advanced equipment like liquid handlers that do more in a smaller amount of space require the user to stand there and feed the machine. This is frustrating for the user, preventing the walkaway time end-to-end automation can provide.

Usability is another significant obstacle. In the lab automation industry, user experience is generally bad across equipment. As several speakers at SmartLabs pointed out, this is a significant reason why adopting digital platforms and automated equipment can be a challenge. There are already cultural barriers to overcome as noted several times throughout the day, so having the smoothest system possible is necessary to increase adoption.

Another challenge lies in maximising the potential of equipment through meaningful connection. A machine operating in isolation is a missed opportunity; a fully automated workflow requires the seamless integration of digital interfaces and physical instruments

Four ways we can change how we think about lab automation today

Fortunately, the industry is addressing many of these challenges. My top four takeaways for how to think about lab automation today are:

1. Design with clear goals: Are you after greater throughput? Perhaps you want to decrease manual touchpoints, focus on more critical work, or create more data of higher quality? It’s important to be clear on what you want from an automated system before you start the process of integrating it. If you don’t think of the end-game you’re not going to achieve what you need. People might think your system is cool, but they won’t know what to do with it.

2. Make your system approachable for your lab workers: One of the issues is that labs install automation systems that are so intimidating and bulky that an already suspicious workforce simply ignores them. My takeaway is that instead of investing in a big box automation system that does ‘everything’ on paper, but in reality lies unused’, we should instead break down workflows into small units of operation and address each of these units. Then, using this insight, we can combine multiple instruments to achieve end to end automation that is actually usable.

3. Digitise from the outset: One of the clearest themes from the event was the need for digital transformation in the lab space. From a lab automation perspective, this means integrating physical automation with automated software, avoiding a disconnect between the two automation solutions. “We’ve talked about all these robots creating a tsunami of data; there need to be solutions for automating the data processing piece too,” remarked Sylvain Demanze, Senior Research Scientist, Analytical & Structural Chemistry, AstraZeneca during one roundtable. Thinking about the automation of data is as important as the physical structure.

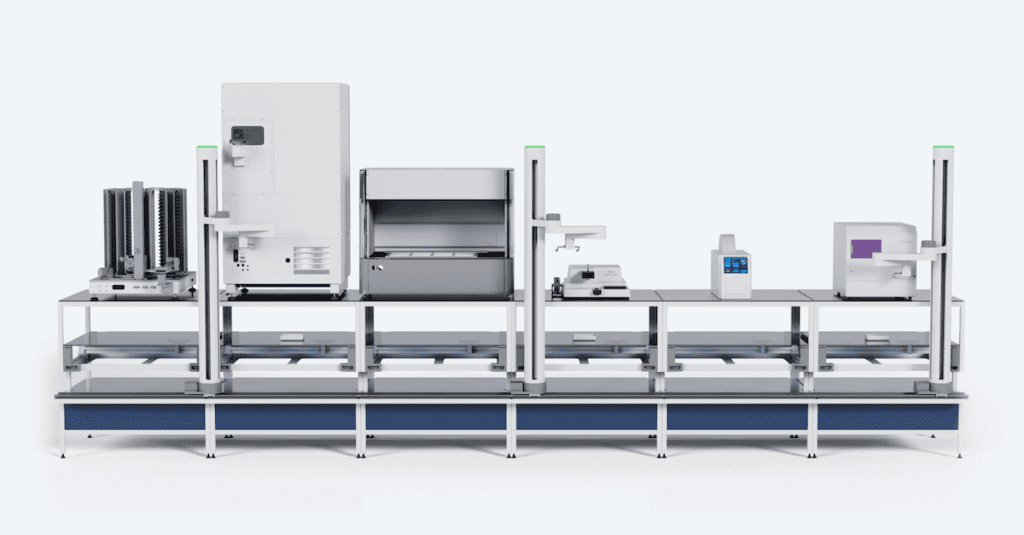

4. Make automation solutions scalable: The LEGO analogy is one that comes up a lot in lab automation talks, but it’s an apt one for the kinds of discussions had at SmartLabs. Traditional big box automation systems are not only intimidating, they are also impossible to scale. With a more modular approach, you can install a system then build on it.

How do we approach automation?

Of course, I work for Automata, an automation provider, so I do need to wrap up by discussing our approach to automation.

Open, integrated automation: At Automata, we are building open, integrated automation solutions. That means that we are open in terms of the vendors we use, allowing us to use best-in-class devices to solve the specific problems each lab has. We use this approach to look at each lab’s needs and workflows and integrate different devices to solve their specific needs.

Capability-centric approach: If we can break down workflows into discrete units of operation then we can achieve two system design goals. 1) The option to implement phased solutions to target core pain points, and help to drive implementation and adoption and 2) Increased parallelisation within a system by adding in multiple units of operation to de-bottleneck workflows.

Human/robot collaboration: In labs, interoperability is normally dealt with using deeply mechanical interactions with solutions. However, our solutions are built with humans in mind. This means that users can walk up to our solutions and easily interact with them.

Stitching together modular devices for scale and adaptability: For labs looking to increase throughput, it’s not just about building more capacity – there’s normally a blocker or a bottleneck in the workflow. Addressing the blocker using a modular approach unlocks the ability to bolt on more devices and increase throughput simply and effectively. For example, with this approach it’s easy to add more analysers because you just bolt on a new lab bench with those devices.

To conclude: What does the lab of the future look like? I believe it’s a space that’s highly collaborative, where multiple devices are connected together in a familiar space. This will allow lab workers more walkaway time, and generate highly contextualised and reproducible data in a human assisted, but fully automated way.