Unlocking the power of your people with true walkaway automation

Labs looking to scale up need to unlock the power of their people to really drive innovation forwards. See how throughput, reliability and ambitions in your lab can be improved with automation in our latest new article.

The life sciences industry is expanding rapidly, with new innovations and discoveries being made by the day.

With this increasing level of demand, on top of a growing skills gap, and with UK lab space at capacity, labs can no longer afford to be a space where highly educated scientists are locked to benches performing manual tasks.

Automating specialised, individual benchtop instruments – like liquid handlers or plate readers – is really just the start of the automation journey. It relieves some of the repetitive tasks lab teams conduct every day, but people are still spending hours on manual steps like moving samples between instruments.

This approach to automation won’t enable labs or people to reach their full potential.

A new approach is needed, one that allows labs to respond to demand, but more importantly one that empowers the very people at the forefront of a new era of scientific innovation.

We believe that approach is open, integrated automation (OIA).

Achieving true walkway time

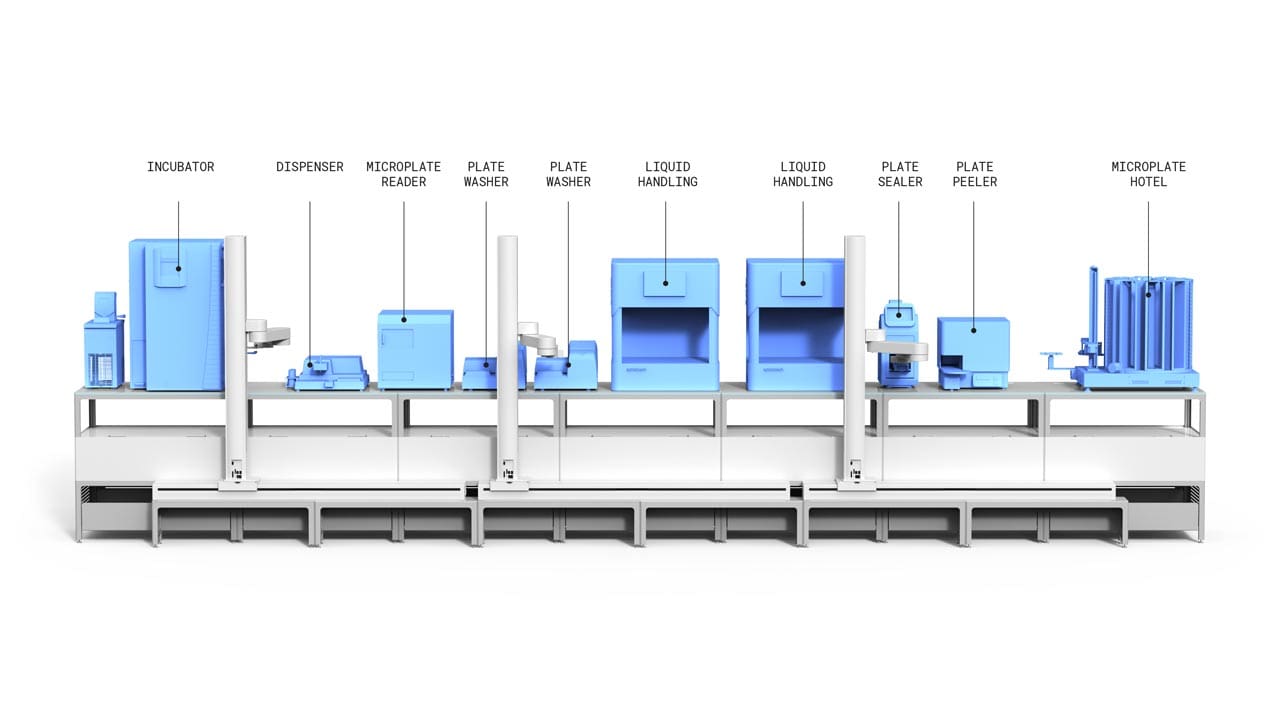

OIA involves robotically and digitally connecting multiple devices.

It looks outside of individual instruments, and instead tackles the challenges holding labs back, building solutions that address them completely to truly unlock the potential of lab spaces and the people within them.

LINQ is our first open, integrated automation solution for life science laboratories.

The LINQ lab automation platform can take your existing set-up and transform it, allowing end-to-end workflows to be fully automated, removing manual touchpoints almost completely.

Imagine what your people could achieve with a solution that allows them to truly walkway.

Removing manual touchpoints with LINQ

Not only do open, integrated automation solutions like LINQ allow scientists to focus on innovation rather than tasks, they reduce the risk of human error and contamination while allowing the lab to significantly increase throughput and turnaround times.

One virology contract research organisation we worked with fully automated their ELISA process with incredible results:

80 – 95.25% reduction in manual interaction

Increased data quality with actions fully traceable

Significantly Reduced risk of manual errors

A THROUGHPUT OF UP TO 530 MICROPLATES PER DAY

Built on the Automata LINQ robotic lab bench, the new automated ELISA system was created with modularity in mind so the lab could expand or adapt it over time, while our LINQ Cloud software was used to seamlessly connect each activity in the ELISA workflow. With each piece of equipment newly being able to operate concurrently, capacity was maximised, throughput was increased, and manual interactions in each assay were significantly decreased.

The power of scientists

Here are some of the ways this powerful form of automation can be the key to putting the power back into the hands of your people.

1. Throughput

Scientific discovery requires large data sets, where high numbers of samples are processed.

In a manual situation, processing these large sets of samples would require long hours for employees, especially if working to an external deadline. However, in a lab with an open, integrated automation system like LINQ, this process can be more productive without taking a toll on the workforce.

Automated labs can operate 24/7, even during the most unsociable hours, eliminating the need for teams to work overtime that’s often spent just waiting for tasks to complete.

For a genomics lab we worked with on automating their quality control process, we reduced the time needed for manual setup for 200 samples from 6 hours 10 minutes, to just 15 minutes.

2. Reliability

It is estimated that 70-80% of all healthcare decisions affecting diagnosis or treatment involve a pathology investigation. Yet, in a recent Agilent survey, ‘unreliable results’ were ranked as the number one factor impacting productivity in labs.

No two people will perform an action in exactly the same way, but when it comes to scientific testing and development, repeatability and standardisation are essential to maintaining a controlled environment. Even slight variations could lead to further errors down the line and render the experiment unreliable.

Automation is the best way to improve the quality of results while giving time back to scientists.

Robots are able to continuously perform the same task without variation, generating a high volume of accurate results, improving the quality of the overall data and therefore any scientific analyses performed.

Automata’s solutions have helped a number of labs reduce their manual set-up time.

In a genomics quality control workflow working with 200 samples, for example, manual touchpoints could be reduced from 1,388 to just 7 using smart benches connected through robotic arms and our magnetic transport layer.

3. Ambition

The heart of a lab is ultimately the scientists who work there.

In an industry where accuracy and efficiency are paramount, open, integrated automation can help relieve scientists of the burden of manual processes by taking on these tasks. It can remove interactions with hazardous materials, improving lab safety, reduce the risk of repetitive strain injuries, and helps talented individuals reach their potential.

With OIA, teams empowered to work alongside machines for ultimate lab effectiveness are left free to achieve big within a safer, happier environment and that is why automation is important.

The success of not only your laboratory but of life sciences as a whole relies on its people. Help them with automation and see what real innovation looks like.

Why is lab automation so hard to use? And why does it…

Read more Balancing usability and functionality

Imagine what potential could look like for your science lab if you…

Read more Unlock the potential of your science lab with automation

Discover how you can supercharge your lab’s productivity, increase efficiency and save…

Read more How to improve laboratory productivity