Scaling cell culture processes

As demand for cell culture increases, labs are under pressure to scale. Reducing manual processes is critical

Due to the increasing use of cell culture methods in research, the production of food and beverages, and the production of active plant compounds for use in medicines, pigments, and flavourings, demand for cell culture has increased dramatically in recent years. The pressure to develop monoclonal antibodies and cell-based vaccines is also contributing to the focus on the industry today.

However, while demand has increased, scaling the processes involved in cell culture while maintaining the quality of the results remains a significant challenge for labs.

In this article, we identify the challenges of scaling cell cultures, different approaches to solving these problems and why eliminating manual steps from the process is so critical today.

The shortcomings of manual cell culture processes

Cell culture has become a major pillar of modern science due to the many uses it affords. Growing cells in vitro allows basic research on disease pathology, provides cellular factories to produce recombinant therapeutic proteins, for production of cell-based therapies within the emerging field of regenerative medicine. The scaling of cell culture processes has remained one of the leading challenges within the biotechnology sector since the first blockbuster biologic of recombinant insulin was produced from cultured Escherichia coli over 40 years ago 1 .

Establishing, maintaining, and expanding highly sensitive cell cultures outside of their native physiological setting is a labour and time intensive process. Many of the repetitive processes involved in cell cultures are still conducted manually. As a result, scaling a cell culture lab setup is traditionally tackled through increased manpower – an inefficient solution that rapidly drives up costs.

The very nature of growing viable organisms means cell culture labs are 24/7 operations that require extensive training of large workforces. Even after implementing the required manpower to enable scaling, quality is not guaranteed due to the technical challenges of large-scale cultures. The repetitive nature of manual laboratory techniques also makes it particularly prone to human error and experimental variability.

The challenges of scaling cell cultures

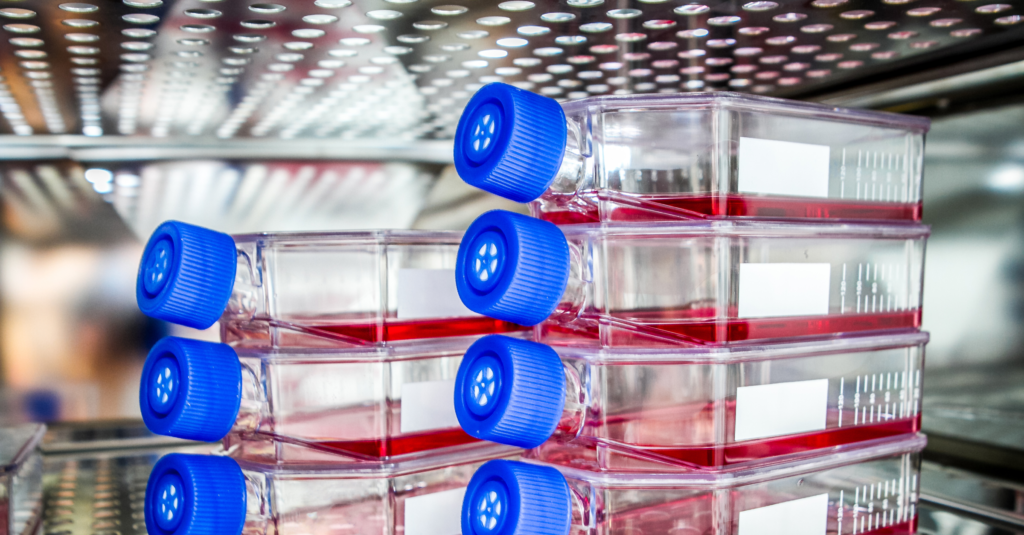

The major issue facing cell culture scale up is the rapid increase in vessel surface area that is required to grow large quantities of cells.

Most cell lines used at pre-industry stages, including academia and pre-clinical stages, are adherent in nature and require attachment as monolayers to a fixed surface. The requirement to be grown as a single cell-thick monolayer means that the only option to scale adherent cell production is to increase the surface area of the cell culture vessels being used (flasks or roller bottles). This rapidly increases the footprint of the process and has a major impact on cell culture lab requirements; additional incubators, tissue culture hoods and operators are required to handle the extra vessels at a great labour and cost expense. With increased scale comes the burden of maintaining each and every vessel, including monitoring of cell counts/confluency, cell morphology and phenotype, pH, and glucose and growth factor concentrations2. These parameters need to be maintained within strict limits and be consistent across all vessels to ensure a homogenous cell population.

When combined, these aspects culminate in an extremely high manual workload. Technicians are required to prepare reagents, coat tissue culture flasks, dissociate and plate cells during passaging, and routinely change the culture medium. Doing so at a scaled level of dozens of flasks while maintaining quality control requires a particular cell culture lab design that can be unfeasible for many laboratories. Although the use of suspension culture-adapted cell lines and large-volume bioreactors at the industrial level solves some of these challenges, extensive process development is required during the scale up process that is only realistic for commercial cell products.

Approaches for scaling cell culture

The scale up of cell culturing can be achieved by increasing the volumes of the culture process and by improving the efficiency through lab automation.

Increasing the volume of the culture process

Increasing the volume of cell culture requires an intelligently designed cell culture lab equipment that maximises the cell culture area. Many novel approaches have been implemented to optimise lab equipment for cell culture scale up. The traditional cell culture scaling process gradually increases the surface area of the culture vessel, taking cells from multi-welled plates to tissue culture flasks ranging from 25 to 225cm2, before finally reaching the largest laboratory scale of multi-layered flask systems. Each stage can also be scaled-out, referring to the use of multiple culture vessels in parallel to increase the scale rather than increasing the volume of the vessel(s) itself. The use of multi-layered systems is a scale-out approach to maximise the yield from a given footprint by essentially stacking many interconnected culture flasks. Often termed ‘cell factories’, these stacks have the same footprint area as conventional culture flask, while offering cell culture areas of up to 25,440 cm² for a 40-stack system. The interconnected chambers allow for the addition and removal of medium, and dissociation of cells for passaging, across all stacks simultaneously to greatly improve the efficiency of the culture system. However, despite greatly maximising the yield, the process remains cost-, labour- and space-intensive2.

Automated cell culture systems

The amount of innovation happening within automated cell culture systems today is immensely improving the capabilities of labs by providing an efficient solution to scaling. Automation additionally offers increased control of the cell culture system by reducing human error and technical variability. Doing so improves quality control and assurance, and rapid iteration and innovation due to improved throughput.

Many laboratory processes have now been automated. Automated cell culture liquid handling devices can replace manual pipetting and have been validated to achieve faster and more precise cell seeding in comparison to manual seeding by a trained staff member3. Automated methods for imaging and counting cells have been designed to standardise the classification of cells and colony forming units during the evaluation of hematopoietic stem cell viability and potency4.

However, the true potential of automated cell culture processes is fully realised when they are performed in tandem to create a fully automated process. The inclusion of robotic arms can bridge individual automated steps, for example by moving a newly seeded culture flask from the liquid handling unit to the colony counting station for analysis, before delivering the flask to the automated cell culture incubator. Fully automated stem cell culture systems can now culture, passage, incubate and morphologically analyse stem cells all from the sterility of a sealed and fully robotic unit5. The capability to produce human stem cell cultures 24/7 and 365 days a year offers a scaling solution to overcome the traditionally prohibitive cost of producing human stem cell therapies at an industrial scale6.

Most importantly, automation does not necessarily aim to remove human input, but rather allows for the utilisation of staff skills for more important aspects rather than repetitive techniques. Coupling volumetric scaling techniques with automated processes offers the most effective approach to increase cell culture capabilities and expediate discoveries, while also reducing variability and production cost in the long term7.

Learn more about automating cell cultures.

References

- Chance RE, Frank BH. Research, Development, Production, and Safety of Biosynthetic Human Insulin. Diabetes Care. 1993;16(Supplement_3):133-142. doi:10.2337/diacare.16.3.133

- Kropp C, Massai D, Zweigerdt R. Progress and challenges in large-scale expansion of human pluripotent stem cells. Process Biochem. 2017;59:244-254. doi:10.1016/j.procbio.2016.09.032

- Rothmiller S, Balszuweit F, Menacher G, et al. Validation of automated pipetting systems for cell culture seeding, exposure and bio-analytical assays in sulfur mustard toxicology. Toxicol Lett. 2020;320:80-86. doi:10.1016/j.toxlet.2019.12.003

- Velier M, Chateau AL, Malenfant C, et al. Validation of a semi automatic device to standardize quantification of Colony-Forming Unit (CFU) on hematopoietic stem cell products. Cytotherapy. 2019;21(8):820-823. doi:10.1016/j.jcyt.2019.06.005

- Panasonic Apparatus Enables Nonstop iPS Cell Culture | Video Review. Panasonic Newsroom Global. Accessed April 10, 2022. http://news.panasonic.com/global/stories/2021/86296.html

- Huang CY, Liu CL, Ting CY, et al. Human iPSC banking: barriers and opportunities. J Biomed Sci. 2019;26(1):87. doi:10.1186/s12929-019-0578-x

- Bellani CF, Ajeian J, Duffy L, Miotto M, Groenewegen L, Connon CJ. Scale-Up Technologies for the Manufacture of Adherent Cells. Front Nutr. 2020;7. Accessed April 10, 2022. https://www.frontiersin.org/article/10.3389/fnut.2020.575146

Leading US research center, Duncan Neurological Research Institute, partners with Automata to…

Read more Leading US neurological research institute, Duncan NRI, partners with Automata

Lab layouts, until the introduction of automation, had seen little change in…

Read more Automation holds the key to unlocking the lab of the future

We explore common problems in plus the advantages and disadvantages of plant…

Read more Plant tissue culture: how automation can help