Open, integrated automation. The premise sounds simple – enable labs to automate their workflows without compromising on lab space or instrument access.

The reality, however, is that conventional lab benches have barely changed in decades, and a more fundamental rethink of this underlying platform is required to enable automation that is both open and integrated.

Our answer is Automata LINQ, a combination of hardware and software that increases both throughput and walkaway time in a way that’s straightforward to adopt.

In this post, we’ll take a closer look at our hardware, the LINQ Bench, and how we reimagined the lab bench for automation.

1. Familiarity through form-factor

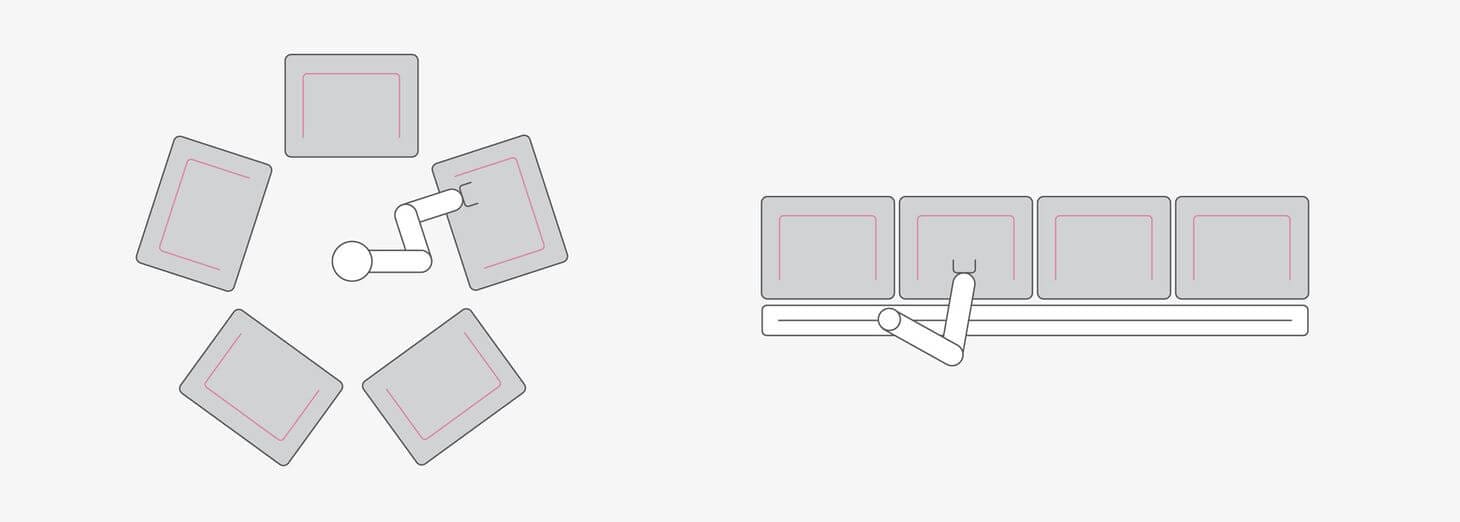

Many existing automated solutions require instruments to be positioned around a central robotics platform. This requires labs to dedicate a space for automated workflows that renders their instruments and labware inaccessible to users. The lack of accessibility also makes set-up and calibration very difficult.

When designing the LINQ Bench, we closely followed the dimensions and layouts of traditional lab benches.

This may sound simple, but it ensures the LINQ Bench can be installed in any lab where conventional benches can currently fit, allowing even the smallest of spaces to have automated and accessible workflows.

Furthermore, it means we can accommodate all the instruments and labware that conventional benches allow, maintaining our position as a vendor-agnostic solutions provider.

2. Modular by design

Every lab is different. Enabling the LINQ bench to adapt to any lab shape and size was key for maximising adoption.

We championed modularity throughout the design process to give the LINQ Bench three highly valuable features:

- Flexibility – to match the specific shape and size of each lab

- Adaptability – to change to the requirements of new or updated workflows

- Scalability – to increase throughput over time, allowing additional benches to be added (or removed) as and when needed

This is why the LINQ Bench can be configured and re-configured in a number of layouts – side-to-side, back-to-back, inside and outside corner, and combinations of all four. Whether a workflow requires two benches, or twenty, the LINQ Bench provides the platform.

3. Layered functionality

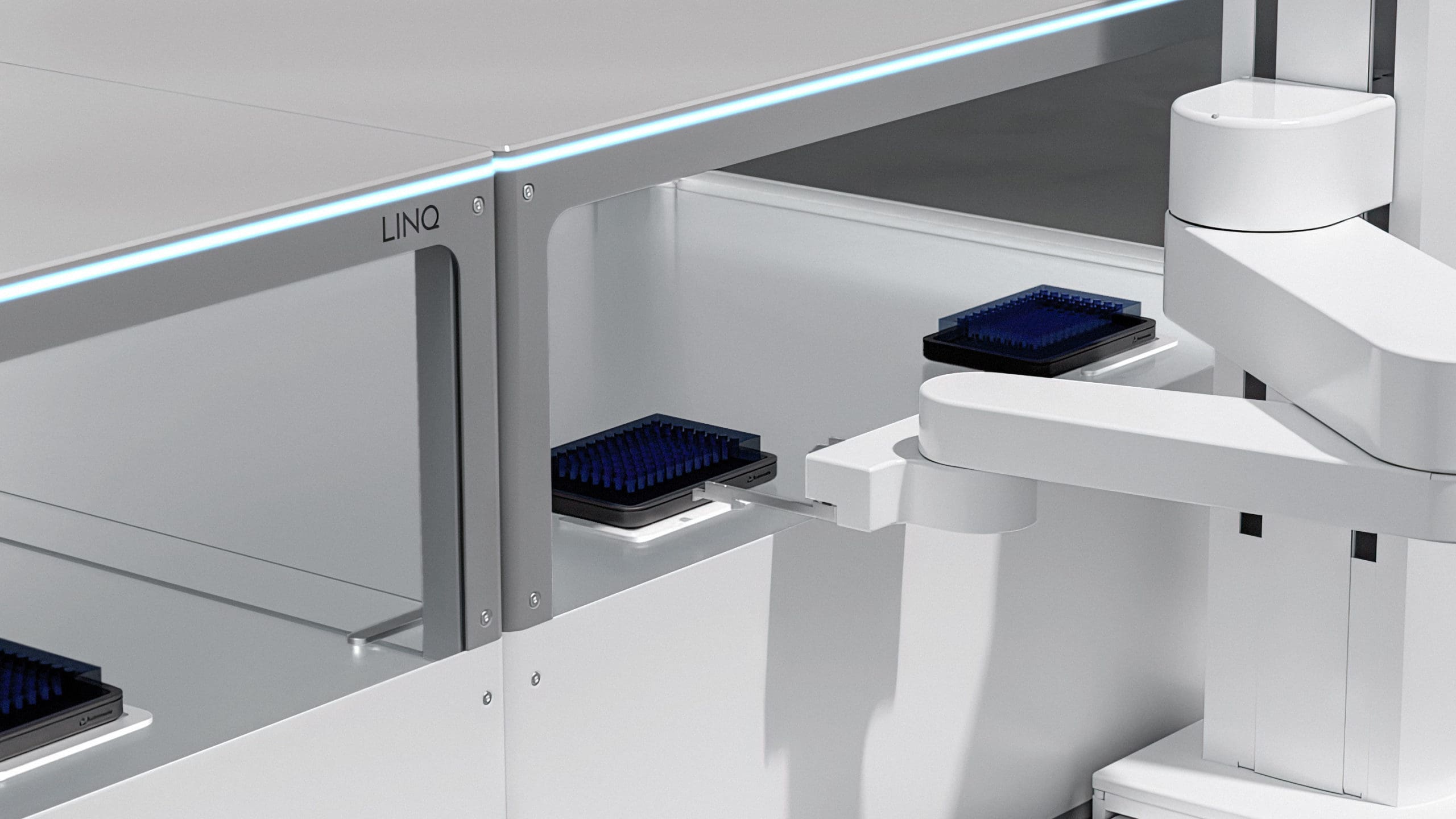

To help users understand the different functional aspects of the LINQ Bench, we implemented stacked layers as a key part of our design language.

These vertically stacked layers emphasise the horizontal connection from bench to bench, while serving to highlight the role of each layer and its connection to the platform as a whole.

One of these functional layers, and a unique element of the LINQ Bench, is the Transport Layer.

This is an automated transfer system that can interface with the SCARA (robot arm) and transfer samples from bench to bench in any direction. It is a vital tool in increasing throughput and increasing the productivity of the SCARA. It is celebrated as its own distinctive layer of white in our vertical stack, while the worktop, various structural elements, and lighting, all represent their own distinct layers.

4. Clarity through lighting

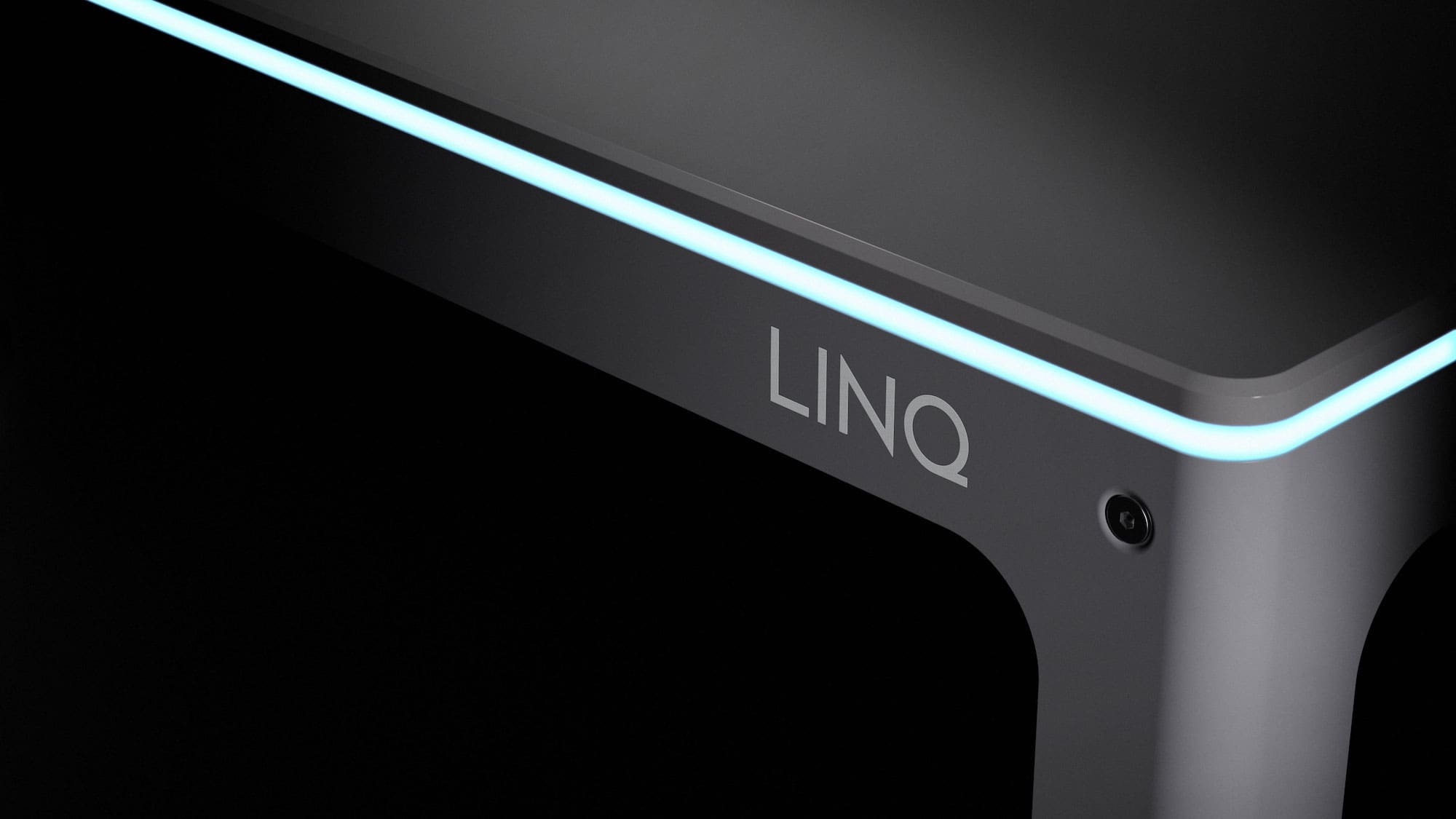

Another key design signature of the LINQ Bench is the Light Layer.

This is a 360° seam of light that’s sandwiched between the worktop and bench frame. It provides a highly visible and responsive feedback interface.

The Light Layer synchronises with the LINQ Cloud software, indicating system status and condition through a combination of colour coding and animation behaviours. This improves user feedback – helping indicate complete workflows, when the system is safe to approach for manual use, and the location of any required manual interactions, for example.

5. Empathic design language

We have honed our design language to strike a balance between bold identity and contextual empathy. Our hardware is distinctively and proudly Automata while remaining calm and complimentary when paired with any number of lab instruments and environments.

We balance precision with softness throughout our hardware, semantically referencing scientific instruments without becoming too clinical or sterile. When combined with our overtly neutral colour palette and practical approach to materials, we create hardware that has both timeless appeal and contextual relevance. This is why the LINQ Bench looks at home in any lab.

The future of LINQ hardware

We’re already starting to see the impact of LINQ.

In the case of genomics workflows, for example, we’ve seen one customer’s throughput increase from 16,000 a year to 50,000 with manual interactions reduced by 88%.

These kinds of figures are a game-changer for the way labs can work and the potential impact on people’s lives. Research is accelerated, discoveries are made faster, and patient test results are returned quicker than ever before.

As we continue the deployment of LINQ throughout 2023, we will get more data and user feedback, and see even greater impact as more labs automate.

What excites us most, however, is this is just the beginning of our hardware journey – we can’t wait to see how LINQ evolves as we integrate new features, develop the design, and roll-out future generations.

For a demo or discussion about how LINQ can revolutionise your lab, get in touch today.

Flexibility is crucial for future-proofed automation solutions. Here are five reasons why

Read more Should I purchase my lab equipment with OPEX or CAPEX budget?

Winner in the Product: Medicine/Health category Automata is pleased to announce that…

Read more LINQ wins iF Design Award

Pantea Razzaghi, Head of Design at Automata explains why scientists are turning to robotics…

Read more Bridging the gap between laboratory scientists and designers