LINQ: the complete lab workflow automation platform

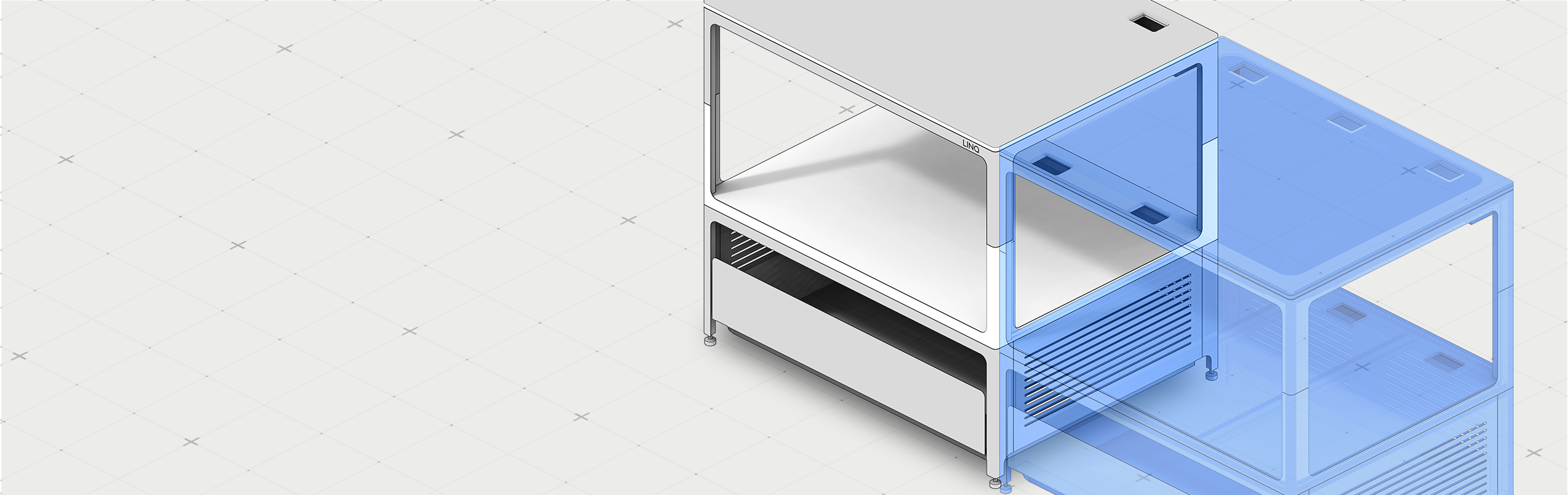

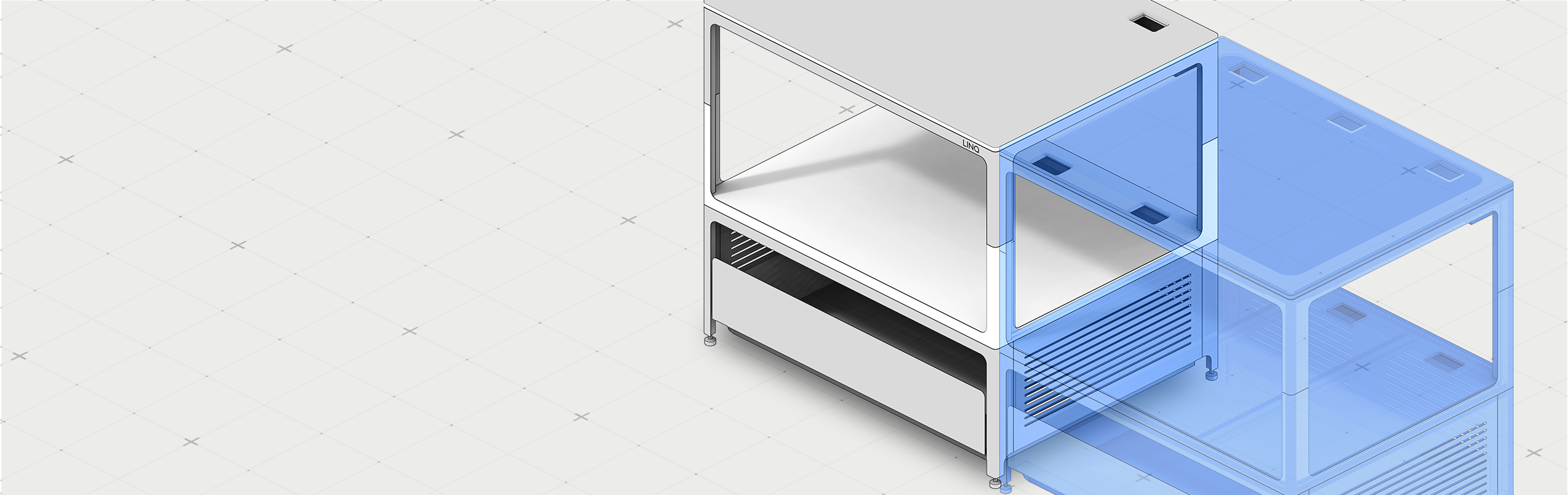

Combining cloud-based workflow scheduling software with a robotically enabled lab bench, LINQ integrates instruments at the touch of a button for the ultimate in flexible workflow automation

We’re here to help

We’ll be in touch shortly

Your lab’s LINQ to full automation

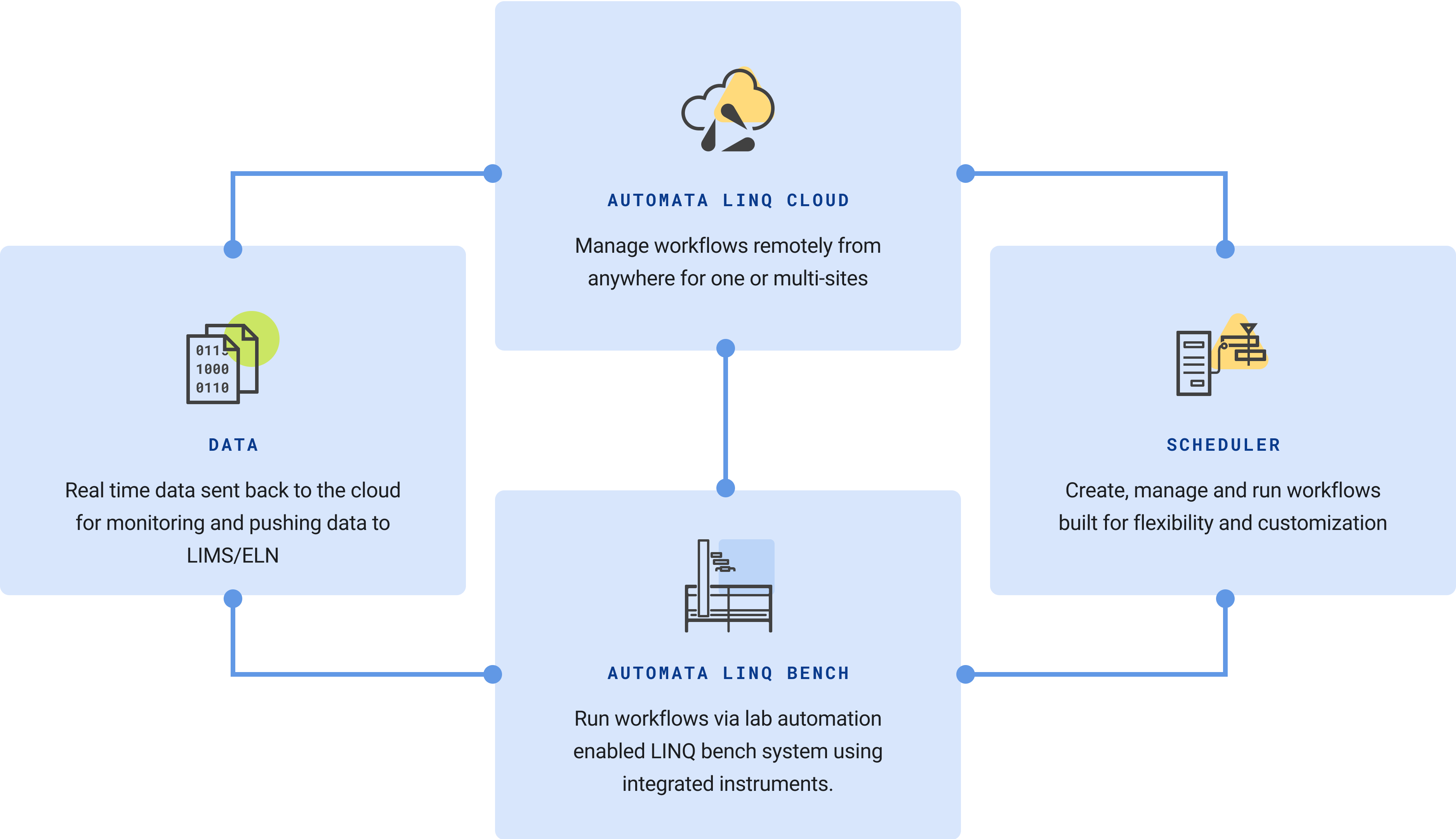

LINQ is the leading automation platform that digitally and robotically connects every component of your lab without compromise to create fully automated end-to-end workflows.

LINQ Bench is modular and vendor agnostic, allowing most lab instruments to be integrated in any space; while LINQ Cloud features a familiar canvas-style interface and Python-based customisation, providing the perfect balance between controlled access and user experience.

Whether you’re looking for a solution that can improve throughput or quality, relieve staffing pressures or space restrictions, or keep you flexible in the face of fluctuating demand, LINQ is the platform for you.

How it works

Design your LINQ lab solution

Whether you’re excited to see how your workflows could be

integrated on the LINQ Bench, or just want some inspiration,

discover our latest tool the Automata Lab Configurator and

visualise your lab today.

Some of our clients

Run the numbers

Unlock your potential

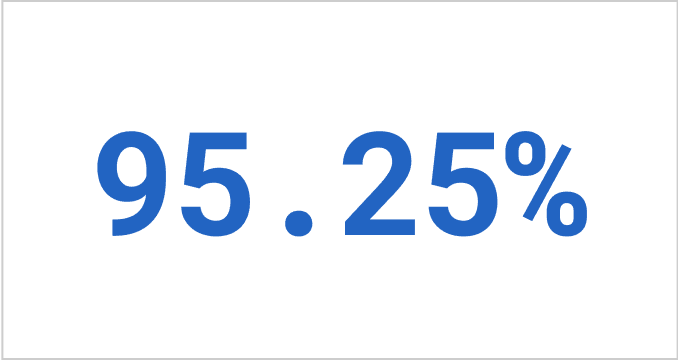

Increase in throughput, from 50-250 plates a day

Scale your lab’s throughput, while you deliver more data of better quality with open, integrated automation.

Unlock your People

Reduction in manual interactions

Eliminate repetitive manual steps and out-of-hours work. Your people are empowered to focus on what really matters with truly hands-free automation.

Unlock your space

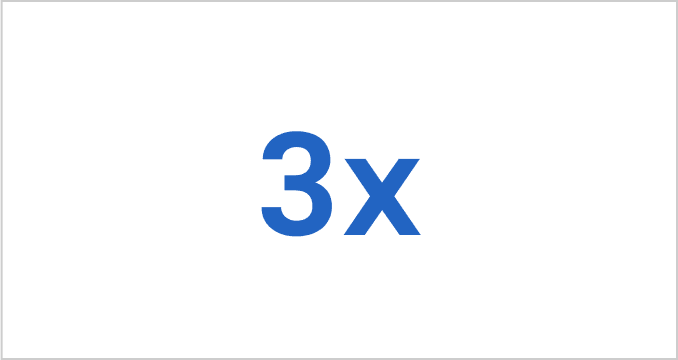

Increase in throughput in the same space

Reap the rewards of lab automation today, without disrupting your current lab space or your existing staff.

Application of Automata LINQ

Genomics

With benchtop automation, genomics labs are limited in their ability to scale, and risk errors and contamination.

At Automata, we believe that in order to usher in the coming genomics revolution, labs need to think about automation differently. They need to embrace open, integrated automation, allowing lab workers to enjoy full walkaway time by robotically and digitally connecting steps in genomics workflows.

Cell biology

Automation is essential to allow cell biology labs to scale over the coming years. While many cell biology labs use automated instruments to eliminate manual tasks, such as plate handling, highly-trained lab technicians still spend hours each day tending to these machines.

As a result, cell biology labs are limited in their ability to scale with most benchtop automation.

Our resource hub

Cloud-first lab automation provides superior benefits to modern labs vs on-site solutions….

Read more The benefits of cloud-first lab automation platforms

Discover what leading biotech innovators shared at our recent event, Advances in…

Read more Bio-automation inspiration from leading global innovators

From diagnosis to treatment, new technologies are revolutionising scientists’ approach to cancer…

Read more Automation in cancer genome sequencing

Your partner from design to deployment, and beyond

A service offering centred on a culture of hypercare

Our dedicated team of specialists represent the largest service support team in automation, ready to walk you through every step of your journey from international deployment to support.