Expert’s view: overcoming the obstacles to cultured meat

We sit down with Marko Storch, Head of Synthetic Biology and Automation, London Biofoundry, to talk about tackling the challenges of lab-grown meat

Since the world’s first lab-grown burger was plated up in 2013, the food industry’s hunger for cultured meat has grown at an accelerating pace.

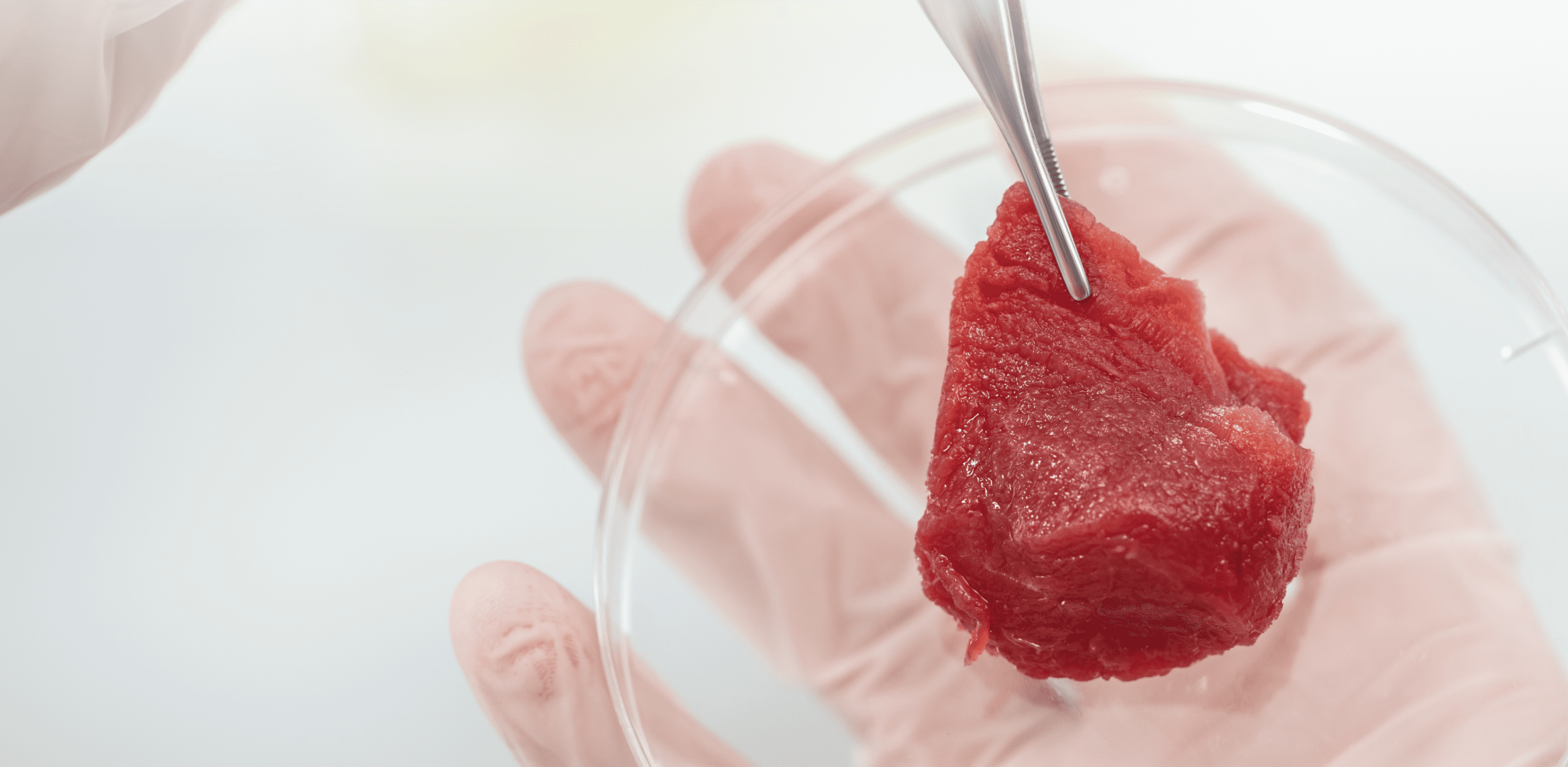

Hailed as a silver bullet for addressing food insecurity, animal rights, and food production health concerns, cultured meat promises an alternative, sustainable way for consumers to enjoy meat products. It is crafted using cells and tissues grown from fat or muscle stem cells.

A huge amount of capital has been allocated to innovation in the cultured meat space since the arrival of the first synthetic burger. Yet, while large strides have been made, and many businesses have sprung up to address the opportunity, significant obstacles remain in the way of the new era of lab-grown meat.

Automata sat down with Marko Storch, Head of Synthetic Biology and Automation at the London Biofoundry, to learn more about the specific challenges, and how the cultured meat industry is working to overcome them.

Consumers hungry for change: why demand for lab-grown meat is on the rise

“Meat production is a huge market, set to grow to over $1tn this decade,” begins Storch. “And current projections suggest that the alternative meat market, including plant-based products and cultured meat, will replace 10% of this demand over the next ten years.”

Cell-cultured meat, or lab-grown meat, is one of the key innovations that will offer an authentic alternative to animal products for customers, he notes. As a result, the market is estimated to be worth an impressive $12.7 bn by 2030.

“Lab-grown meat presents an excellent opportunity for consumers to still enjoy meat products without the many disadvantages our current mode of production entails,” he explains.

Storch identifies three of the key drivers for cultured meat today:

1. The environmental impact of livestock farming: “There are huge external costs associated with livestock farming, some of which might be priced in over the next years ” says Storch.

According to an EY report more than three-quarters of global agricultural land is used for livestock production today. And food production accounts for more than a quarter of global greenhouse gas emissions, with more than half of that emission coming from livestock and fish production.

2. Society’s increasing focus on animal rights: In a survey conducted for the ASPCA, 77% of consumers said they are concerned about the welfare of animals raised for food.

3. Antibiotic resistance in animals: “An antibiotics crisis is looming this century, also driven by antibiotics use in farming,” Storch explains. “We’ve just seen the pain and damage that COVID-19 has caused the world. By continuing to farm animals the way we do, where pathogens and especially drug-resistant ones spread, we are risking the next pandemic.”

Making lab-grown meat accessible and affordable

Back in 2013, Mosa Meat’s first lab-grown burger cost around 250,000 euros ($280,400). While the processes for creating lab-grown meat are becoming more established and affordable, the associated costs are still prohibitive for most customers.

“Cultured meat is a capital-intensive field with high cost factors including cell culture infrastructure, growth media and bioreactors. So, the key question is, can cultured meat be produced at a price point customers are willing to pay?” asks Storch.

He identifies several challenges labs must overcome to bring the cost and quality of cell-cultured meat in line with customer expectations while being able to deliver at the scale the market demands:

1. The development of new tools: “Developing the right toolbox for cell culture, from methods for epi-genetic interventions, to achieving the right media composition with effective growth factors, is a key challenge. There is a huge potential in perfecting these methods.”

2. Reproducibility: “A fundamental problem in biological research is that even slight changes in process mean that the results are no longer predictable or comparable. So there needs to be a standardisation of workflows to increase quality and reproducibility.”

3. Growing cells at scale: “Traditional bioreactor designs are not made for the type of cell culture that cultured meat companies focus on. So, innovation is needed to economically grow the amounts of cells in the composition required for lab-grown meat.”

4. Co-cultured meats: “One of the key challenges in cultured meat is re-creating the texture and taste of real meat. To achieve this, lab-grown meats strive to combine different cell types. For example, including fatty tissues is important for taste and mouthfeel. This means that labs need to develop novel co-culture systems where there is more than one cell type grown in the process.”

5. Safeguarding against contamination: “The last thing you want in your cell culture is contamination which means you have to sacrifice your research result or product.”

Learn more about the opportunities and challenges of the cell culture industry today.

How is the industry tackling these challenges?

“With recent investor enthusiasm, a lot of young companies have sprung up in the last 5-10 years,” says Storch. “For example, companies like Beyond Meat and Impossible Foods lead in plant-based meat alternatives, while Upside Foods and SuperMeat are working on lab-grown meat products.

“As a result, there is a whole ecosystem growing around the cultured meat industry,” he continues. “Smaller companies are popping up focussing on key building blocks to support this ecosystem. Companies such as Multus Media specialise in creating animal-free media that allows cells to grow happily at lower cost, for example.”

Automation is crucial for cultured meat labs to reduce the amount of manual handling involved in the processes, says Storch.

“Cell culture work is typically a very labour-intense process,” he explains. “This means that staff have to spend a lot of time physically attending to the processes. One burden shared in the cell culture community is the requirement to attend cells at inconvenient times, like weekends, conducting the repetitive processes that support the growth or differentiation of their cultured cells. Here, automation can play an important role in reducing the manual, repetitive workload.”

“Another key benefit of automation is that it allows cultured meat labs to run many more experiments in parallel, while reducing human error” adds Storch. “Experiments are more scalable and can address more hypotheses, speeding up the discovery and scale-up process. That’s very useful, especially for companies that are working to a strict timeline.”

Matching cultured meat labs with the right automation solutions

Finally, Storch identifies important features of lab automation solutions for cultured meat labs:

1. Small footprint, modularity and affordability: “The smaller labs supporting the ecosystem don’t always have a lot of space to include bulky and expensive automation platforms but can leverage scalability of modular affordable units.”

2. Reliability: “Labs benefit from a continuum connecting manual and automated workflow formats. Such an architecture provides direct scalability, troubleshooting and backup bandwidth”

3. Integration of diverse instruments: “I think a big issue with lab automation right now is that you have excellent equipment that won’t talk to each other. Automation solutions that integrate equipment from a wide range of manufacturers and abstract the operational processes are ideal.”

Your Guide to the Future of Automated Cell Biology Labs

Start planning your lab’s automation journey with insights on building an impactful and futureproof roadmap.