Three key themes from Future Food-Tech Alternative Proteins Summit

I had the privilege of attending the Future Food-Tech Alternative Proteins Summit in New York last month, and immersed myself in the innovation that was displayed by companies, large and small, from around the world. The alternative protein industry is an exciting place to be. There is real progress being made and engineers are developing and using new processes that will help the industry to scale even faster.

There was a definite air of anticipation and positivity around the possibilities of what could be achieved. However, while nothing seemed impossible, there were specific challenges that stood out. We need clear regulation for novel foods and companies are still experiencing difficulties to scale.

Here are some of the biggest themes and challenges that stood out to me from conversations with the founders and CEOs of the world’s most renowned and ambitious food-tech companies in the alternative protein space.

1. Why cell-cultured alternatives may be the answer to protein shortages

The United Nations estimates that food production will need to double in order to feed the nearly 10 billion people expected to populate the planet by 2050. As for protein, people around the world consumed about 324 million metric tons of meat in 2020, and that number is set to increase even further.

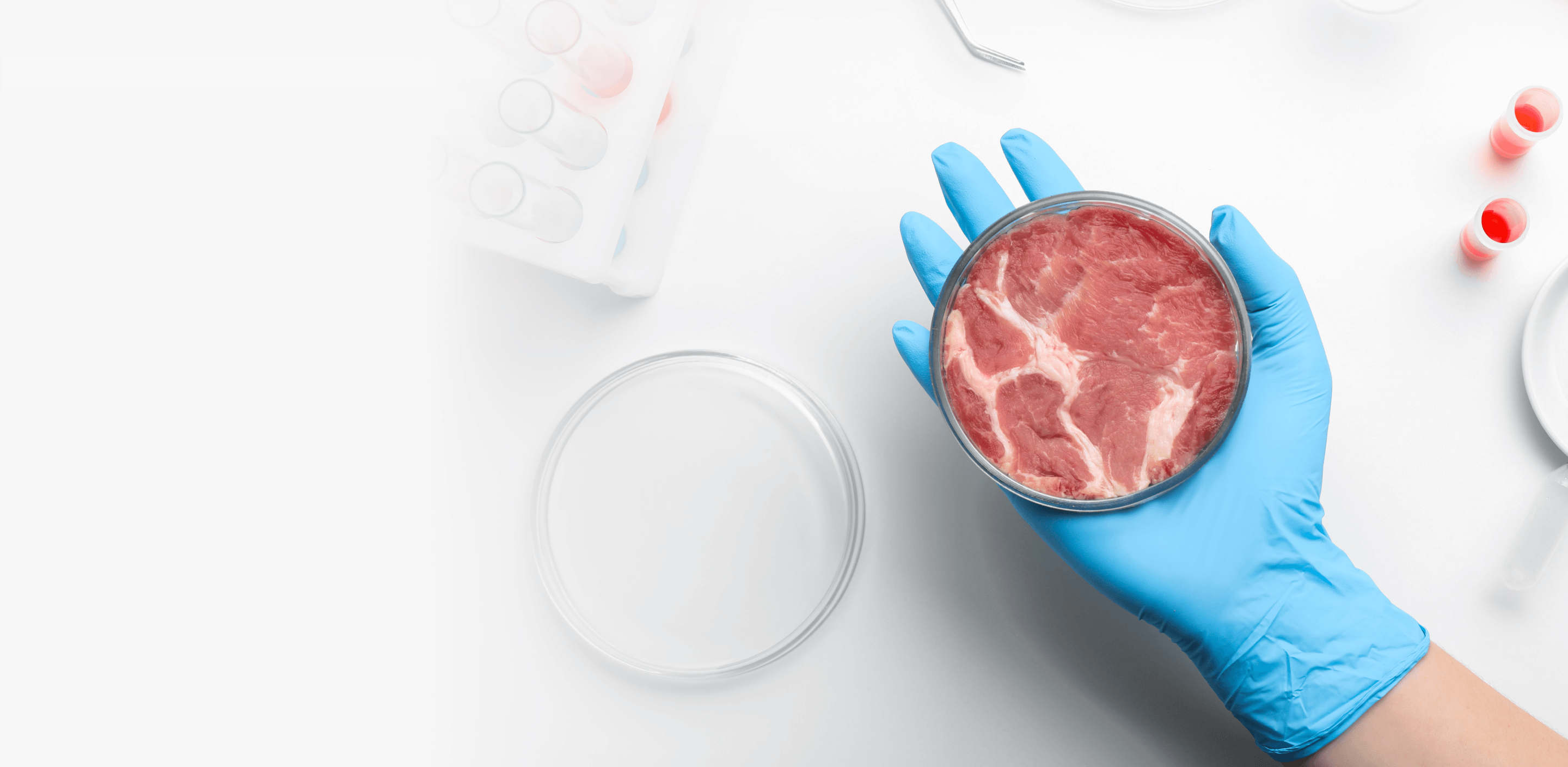

We need to relook at how we cultivate and produce the amount of food needed to feed this growing population. Cell-cultured meat is one protein alternative that could help address it. This process uses stem cells from healthy animals to make meat without slaughter and it promises huge benefits for the environment and consumers given that it’s made in sterile conditions in labs and no antibiotics or growth hormones are involved. This means that more land could be used for sustainable farming or even returned to wilderness, helping increase biodiversity and protect endangered species.

Cell-based seafood derived from commonly consumed fish or shellfish, was another example that stood out at the event. Similarly to cultured meat, cell-cultivated seafood is made in a lab by harvesting cells from a small number of donor fish or shellfish and culturing them in a bioreactor. With rising demand for sustainable seafood solutions, especially amid growing consumer concerns about the devastating consequences of commercial fishing, commercialising cell-cultured seafood has never been more pertinent.

2. The issue of scaling alternative proteins

One theme that stood out at the event was figuring out how to scale your existing workflow. It was apparent that growth over the next few decades will likely depend on investment, sourcing from nearby areas and recruiting talent. They often don’t have the facilities such as the bioreactors and fermenters required to produce large quantities of protein, so identifying how to outsource the necessary resources is a challenge.

Automation can help alleviate some of these challenges by applying it to different stages of the process. For example, it can have significant impact at the early stages where the majority of repetitive processes are handled by scientists. By automating these processes, scientists and technicians will have more time to focus on scaling the development of proteins. The next stage is the development and testing of new flavours and functionality – two major factors in consumer food choices – which could be quite labour intensive. Implementing robotics and automation technologies on labs would alleviate some of that pressure on scientists. The final stage involves quality control and testing. Again, more repetitive tasks but accuracy is critical. Therefore automation can help with standardisation and ensuring consistency of the product for the end consumer.

Find out more in our article on scaling cell culture processes

3. Jumping the regulatory hurdles in the alternative protein industry

The Future Food-Tech Alternative Proteins Summit hosted representatives from the FDA, USDA as well as layers in the food industry, which was a positive sign given there is still no specific consensus as to how to regulate novel foods yet. In fact, regulations vary from country to country, which makes it even more difficult to export novel foods. For example, if a company takes a muscle biopsy from a cow, they can end up producing hundreds of kilograms of cultured meat. However, it’s not yet clear when this cultured meat becomes labelled as food. In Europe, about half a dozen cultured meat companies have started a committee to lobby regulation to the EU.

Regulation and government support are essential for helping future food-tech companies scale and flourish. I had the privilege of meeting with representatives from Israeli companies who are currently leading the way in alternative proteins and food development and was fascinated by their entrepreneurism and innovation. Last year, over $600 million was invested in Israel’s alternative protein startup landscape, representing around 450% year-over-year growth. Most recently the country also earmarked over $1 million for academic research into new food technology – further helping to accelerate progress and meet the evolving needs of today’s consumer. Having this partnership between government, startups, large corporations and academia is what’s driving the food-tech sector forward in Israel, setting a shining example for success for countries around the world.

The future of alternative proteins

The innovation and growth in alternative proteins displayed at the Summit last month illustrated just how exciting the future of food can be. Whether for environmental reasons, diet preferences or nutrition needs, consumer adoption to alternative protein and the continued growth of the plant-based industry are undeniable. And while there are challenges along the way to reach the scale needed to meet the needs of demanding consumers and our planet, innovative technology is here to help alleviate those hurdles, helping companies scale faster.

Your Guide to the Future of Automated Cell Biology Labs

Start planning your lab’s automation journey with insights on building an impactful and futureproof roadmap.