Discover five ways to improve your lab turnaround time that will unlock the potential of your people

Turnaround time (TAT) is simply the time it takes to complete a job, from beginning to end. In a laboratory setting it can be described in three phases: pre-analytical, analytical, and post-analytical (1).

At a time when demand for high throughput laboratories is always increasing, turnaround time should be constantly evaluated in order to enable streamlined processes, keep consistent timings, and to ensure the provision of both accurate and reproducible data.

Automation has become ever more critical for assisting laboratories in keeping lab TAT fast whilst reducing the potential for human error and subsequent lag in efficiency. Let’s explore this further.

Importance of turnaround time in the laboratory

TAT is often used as a benchmark for efficiency and performance within a laboratory (3), and improving it can have tangible benefits for staff and patients alike.

Slow or delayed turnaround times can lead to the need for new samples to be generated and analysed, which increases workload for laboratory staff, while understanding where bottlenecks most often occur allows for more effective workload – and workflow – planning.

In a clinical laboratory setting, meanwhile, optimised TAT is essential for providing fast, accurate results to patients undergoing treatment or diagnosis.

Factors affecting turnaround time in the lab

Previous research has shown that most issues affecting lab TAT tend to occur in the pre-analytical phase, however, there are multiple factors that can affect each phase.

In the pre-analytical phase, issues can arise from sample preparation, labelling and transportation errors.

For example, if blood samples are transported at incorrect temperatures, samples can become haemolysed and therefore unusable, thus requiring new samples to be collected.

In the analytical phase, improvement in areas such as quality control (QC) and calibration have been helpful in establishing this phase as having the least effect on TAT. However, factors such as running out of stock, poor machine maintenance, and under-trained staff can negatively affect TAT.

The post-analytical phase involves the critical evaluation of test results and the subsequent release to the relevant persons. TAT can be affected here by having to manually retrieve results from machines and manually identify outliers instead of having software that can send results with outliers or errors identified to the relevant personnel to be further analysed.

How to improve turnaround time in the lab

Here are five ways that turnaround time can be improved, whatever the application:

- Placing laboratory equipment in a logical manner

This can be as simple as placing a PCR pipetting station next to thermocyclers and qPCR machines to reduce the time taken to complete a part of a job.

- Identify and remove causes of errors, variability, and waste (also known as Lean Six Sigma)

The Six Sigma system has five stages: define, measure, analyse, improve and control (DMAIC). It’s used to determine where problems may lie and then solve them, thus streamlining processes and improving TAT (4).

- Utilising Middleware

Install software that allows for real-time data to be transferred to laboratory information systems (LIS), reducing the time taken to retrieve data from machines and identify outliers. This reduces the risk of human error in data analysis.

- High-quality training for staff

Keeping on top of staff training, and retaining skilled workers allows for processes to be completed faster and more efficiently whilst also reducing the risk of human error.

- Implementing automation

Automation in even the simplest laboratory processes can improve TAT as often it is the seemingly simple processes that take the longest time, i.e., labelling and sample preparation.

Improving lab turnaround time with automation

As mentioned above, automation is one of the key ways in which lab TAT can be improved.

- Automated quality control allows for constant checking on data variability, so performance issues can be identified and flagged to staff automatically

- Specimen handling can be automated, meaning samples can be stored and received without handling, reducing the risk of contamination and human error. Automated handling is particularly impactful where large numbers of barcodes need to be scanned or samples transported, for example

- Using middleware allows seamless transfer of data from machines to the LIS, removing the need for manual data entry and allowing experiment results to be shared faster (5)

Automating the areas above decreases turnaround time and allows skilled workers to use their time more efficiently within the lab.

Open, integrated automation for improving TAT

Automata’s open integrated automation (OIA) solution tackles scale, reproducibility and traceability issues, allowing end-to-end automation that increases turnaround time but doesn’t compromise flexibility.

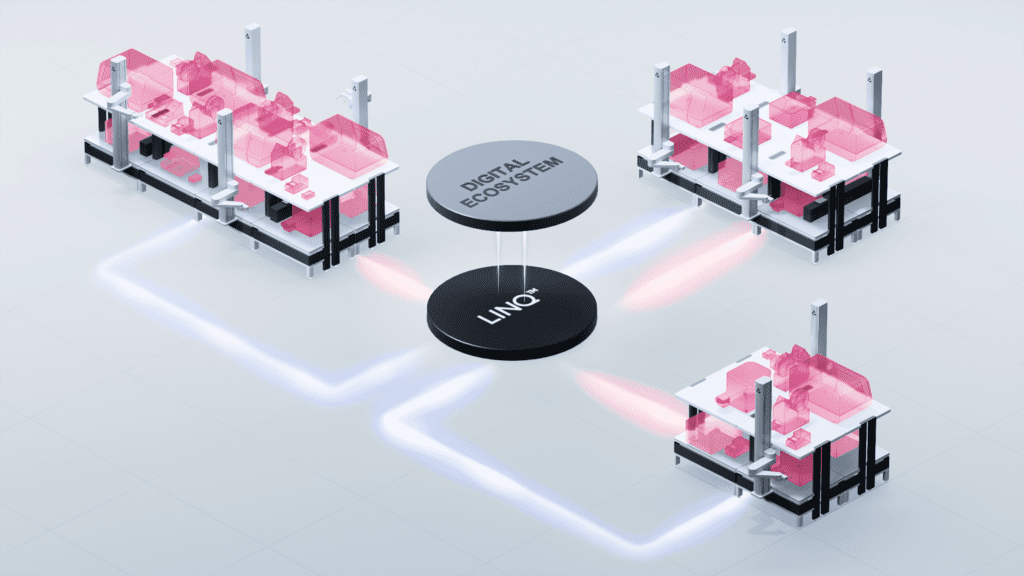

Our open integrated automation platform, LINQ, combines three components to create a lab automation solution that works for any method or lab application: the Automata LINQ bench, the Automata LINQ software, and a world-class service.

Integrating with most instruments and featuring a modular design, the Automata LINQ bench is easily adaptable for any workflow or any existing lab space.

Find out more about LINQ and how it can improve turnaround time in your lab.

Cloud-first lab automation provides superior benefits to modern labs vs on-site solutions….

Read more Why we built LINQ

ELRIG is returning to London with an impressive lineup of exhibitors. Here’s…

Read more Four reasons to visit Automata at ELRIG Drug Discovery 2024 this October

Improve data traceability and create a single source of truth for your…

Read more Improving traceability with lab automation