How to unlock the space in your lab

With lab space almost zero in some life science-intensive regions of the UK, fast-scaling organisations need to explore alternatives to increasing lab size. Is automation the key? Let’s explore.

The future of life sciences hangs in the balance. Not because of funding or ambition, but because of space.

Putting scientific innovation at the heart of growth plans has meant that companies especially in the UK are seeking to double or even triple output in many areas, from genomics to synthetic biology. However, there isn’t enough room for fast-scaling organisations to expand lab operations, so a new approach is needed.

No space in the Golden Triangle

Particularly around established and academically rich locations in the UK, available lab space is almost zero.

Consequently, big life sciences names operating in this Cambridge-Oxford-London ‘Golden Triangle’ find themselves constrained, with no space for expansion.

In Cambridge, lab supply is still below 0.5% and requirements are now topping a million sq. ft.

Bidwells Office and Labs Market Databook

Even locations designated Life Sciences Opportunity Zones – Stevenage, Birmingham, Harwell in Oxford, Cambridge, Wiltshire, and Kent – are space-poor, with some still being in that overcrowded Golden Triangle region.

This lack of space in concentrated biotech and life sciences regions impacts start-up and scale-up businesses seeking knowledge-rich, collaborative areas to move into, as well as established players needing to grow.

Three options for finding more lab space

Moving

There are of course many other countries in the world with equally as impressive life sciences institutions that don’t have similar space constraints. Boston, for example, has millions of square feet of lab space immediately available to tempt investors away (9.9% of space was available as of March 2023).

That being said, UK government investment in life sciences is generous, our academic profile is second to none, and breaking into or relocating to another market isn’t possible or desired by some businesses.

Being in certain territories or regions also has benefits that would be lost in relocation. European pharma giant AstraZeneca was chosen as the preferred partner for the University of Oxford Jenner Institutes COVID-19 vaccine project over the US-based Merck & Co., for example.

Waiting

For those looking to stay, there is new space being developed but competition for that will be rife. For most, though, the time to respond to increased demand is now.

Bidwells report a total of 370,000 square feet of space expected to be completed in 2023 and a more sustained supply pipeline for 2024 but that won’t meet demand.

Some office buildings are being repurposed into lab space, and it’ll be crucial for those facilities to be flexible. Any lab created now must be ready to change as quickly as tomorrow.

Open, integrated automation (OIA) solutions will help.

Rethinking

OIA involves robotically and digitally connecting multiple devices. It looks outside of individual instruments and instead tackles the challenges holding labs back, building solutions that address them completely to truly unlock the potential of workspaces and the people within them.

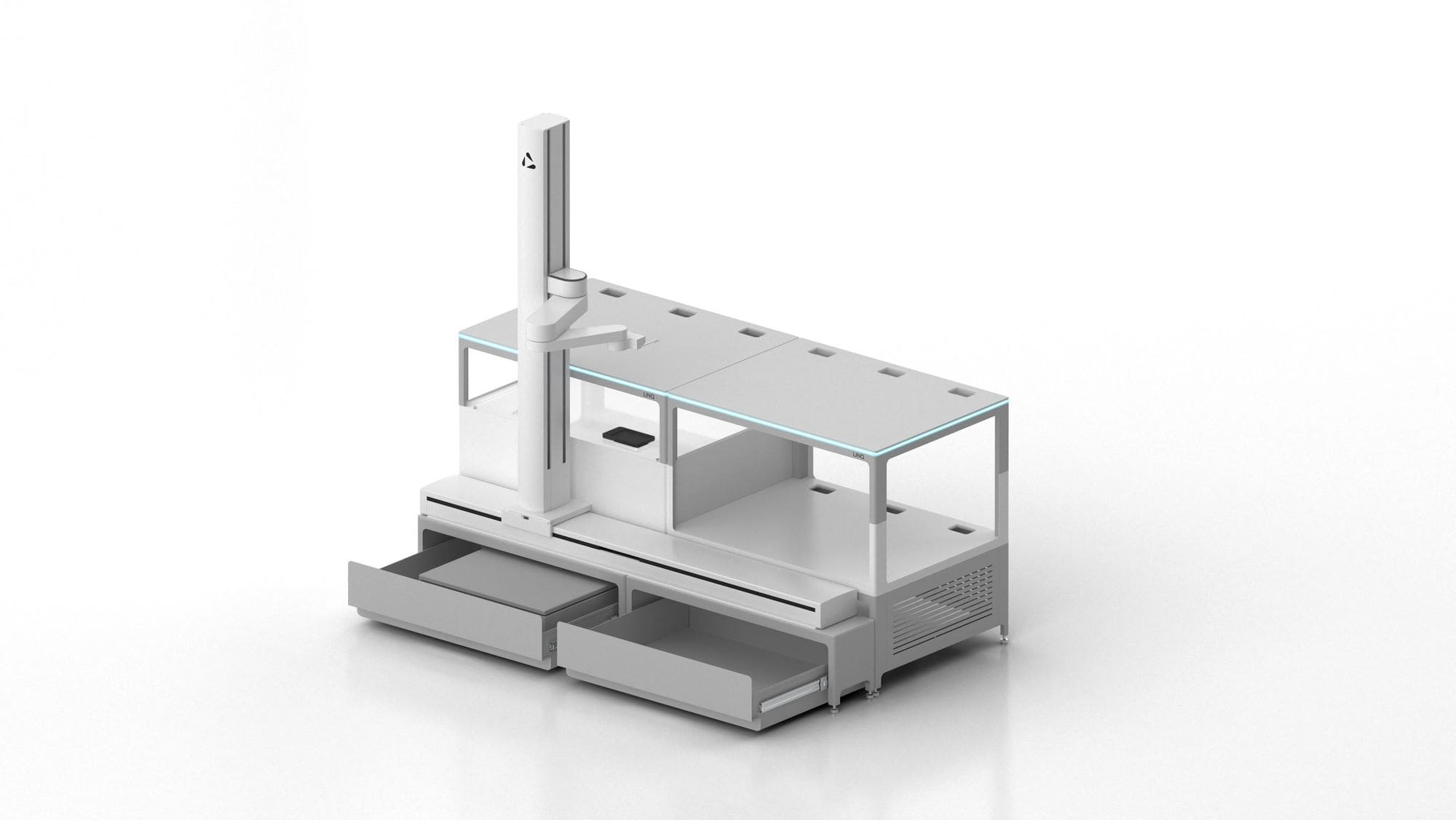

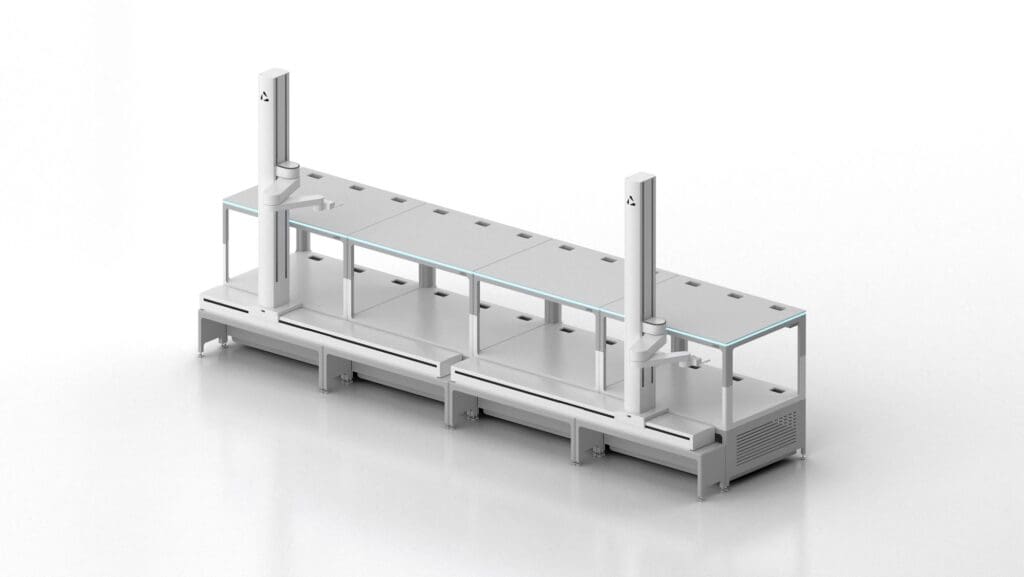

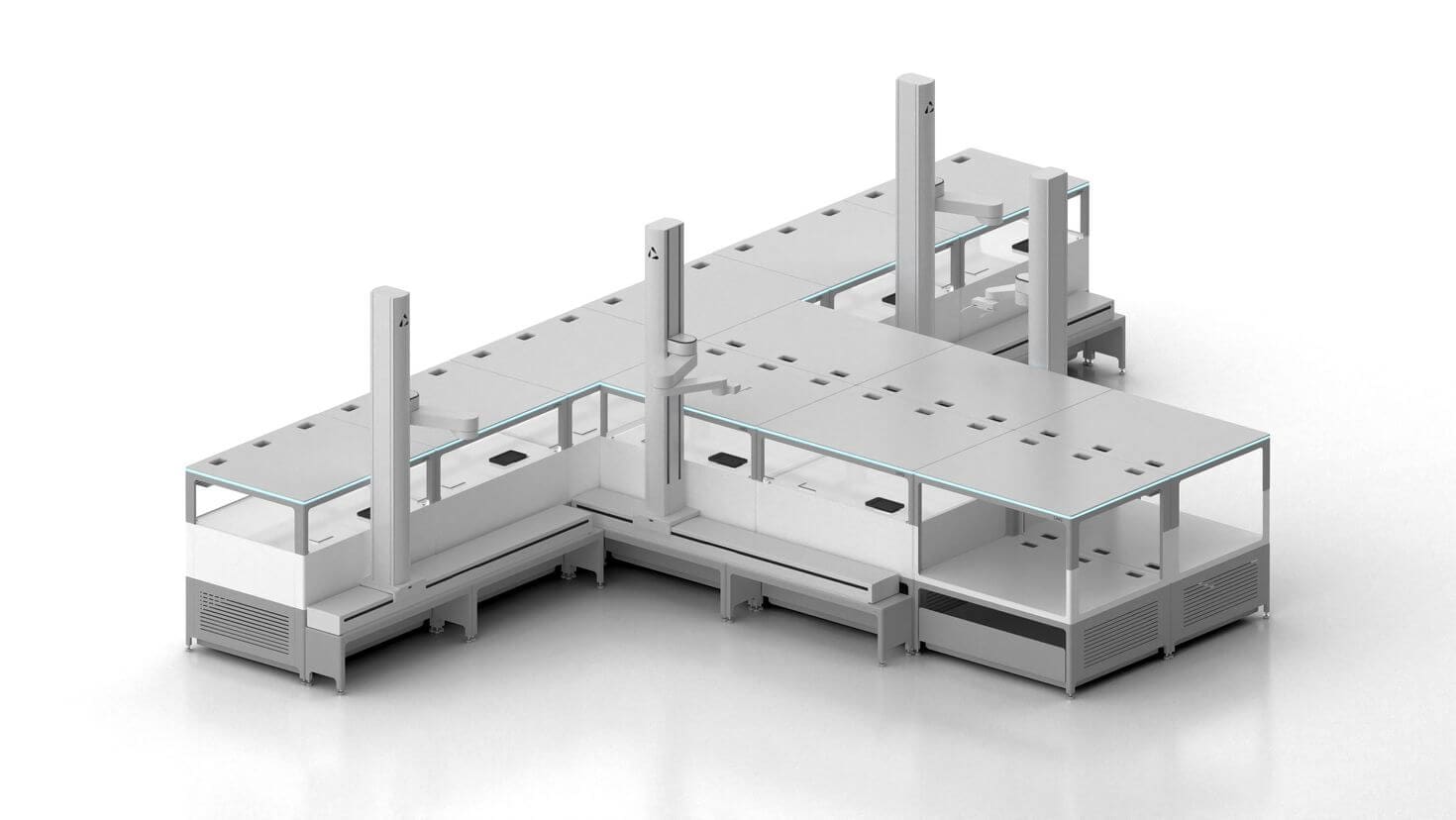

LINQ is our first OIA solution for life science laboratories.

Our ambition is that automation not only protects newly established labs from becoming obsolete or inflexible too soon, but that it removes the need for scale-up relocation altogether.

LINQ combines a truly innovative lab bench that is modular, with flexible dual-purpose layers; software that makes workflow automation programming quick and easy; and world-class service that is there to help you redefine your automation at the drop of a hat.

Just a few of the ways LINQ can be configured

The impact of space-saving automation

We helped one lab increase its genomic testing capacity to go from 16,000 to 50,000 samples a day, with no additional staff.

The lab was also limited by space restrictions, and existing workflows involved disparate pieces of equipment and the manual transfer of samples and data from one workstation to another.

As well as wanting a solution that could grow and develop as their needs evolved, the lab required fast implementation with little downtime and a solution that required only training.

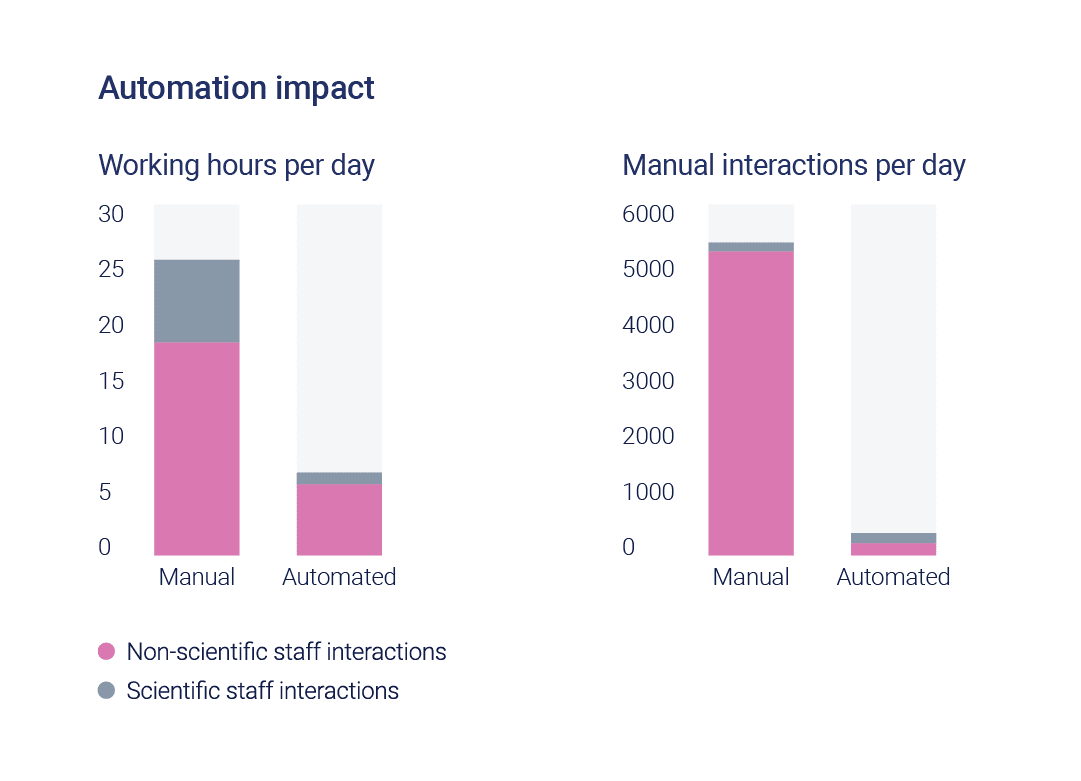

After implementing LINQ in the customers’ lab, throughput was increased with staffing hours decreased, manual handling and associated errors were reduced, and data quality was improved.

Adapt or be left behind

With demand increasing, a skills gap growing, and technological advancements rapid, re-evaluating how you approach automation is crucial for future success and lab growth.

Speak to Team Automata to see how LINQ can help you unlock your lab space today. Our next showcase event will be SLAS Europe this May!

Ready to Scale Up Your Lab’s Efficiency?

Unlock seamless, scalable automation with LINQ, connecting instruments and workflows to adapt as your lab grows.