Truly hands-off ELISA automation

Our fully automated ELISA platform frees your scientists from tending to lab equipment

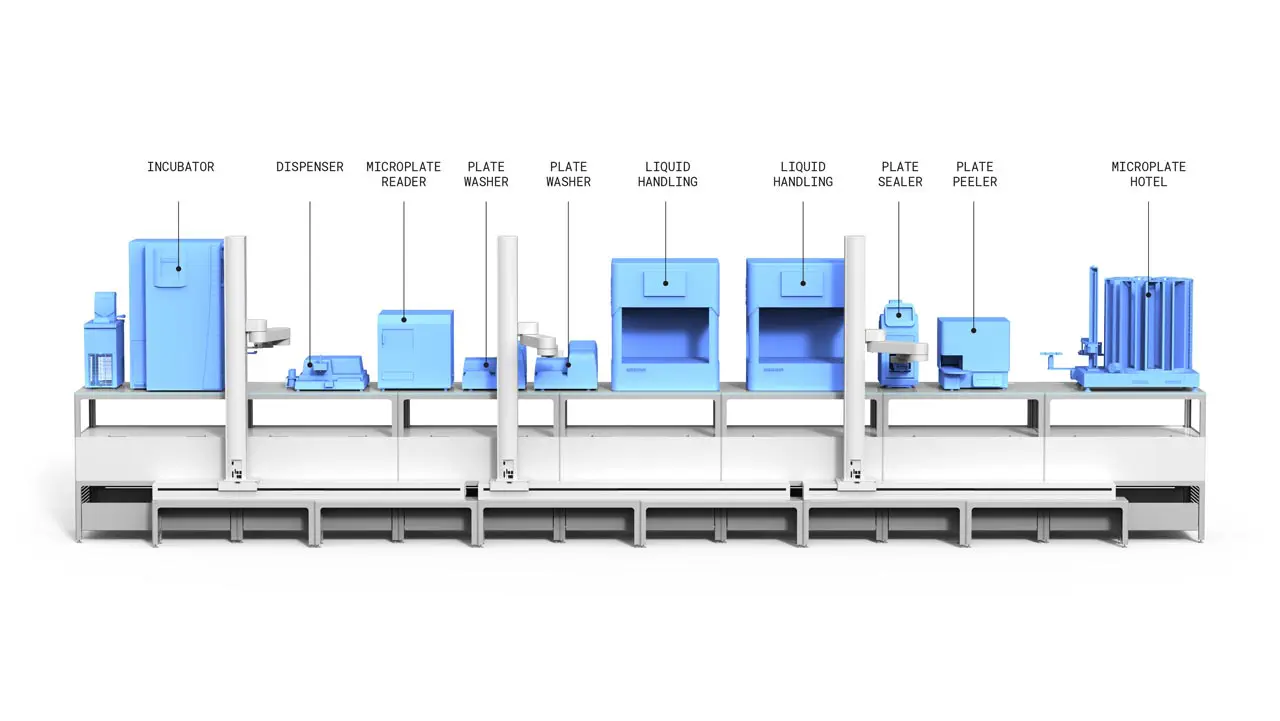

Our approach to lab automation is different. Open, integrated automation works by connecting benchtop instruments with robotics, enabled by the Automata LINQ bench and integrating them together with Automata LINQ software to create a new approach to ELISA automation.

We’re here to help

We’ll be in touch shortly

Thinking about scale?

Go beyond ‘out of the box’ solutions for ELISA automation

Currently, performing ELISA requires many manual steps. Even when automation is used, it tends to be limited to isolated benchtop automation, such as liquid handlers. This means time-poor, highly-trained technicians and scientists are spending hours moving samples between lab equipment, performing manual steps that can lead to human error and compromised data integrity with other benchtop machines when running at scale.

Out of the box solutions that combine multiple steps can help address some of these issues, however they are restricted in their ability to scale due to limited on-deck space, space within a lab, and inflexibility when a lab’s needs change.

Our approach to lab automation is different. Open, integrated automation works by connecting benchtop instruments with robotics, enabled by the Automata LINQ bench and integrating them together with Automata LINQ software to create a new approach to ELISA automation.

What is automated ELISA?

Automated ELISA is simply executing some or all aspects of the assay using some kind of machine-based automation. This automation could be benchtop – for example having a robot pipetting rather than a human – or end-to-end, which would see digital and robotic connections used to conduct the majority of the design and implementation of the immunoassay workflow with minimal human intervention.

Scaling up with our automated ELISA solution

We worked with a virology contract research organisation (CRO) to design a fully automated ELISA system to maximise throughput, provide robust data management and significantly reduce manual interactions.

80 – 95.25%

REDUCTION IN manual interactions

UP TO 530

MICROPLATES PER DAY THROUGHPUT

REDUCED RISK

OF MANUAL ERRORS

Built on the Automata LINQ robotic lab bench, this ELISA system has equipment operating concurrently, unlocking a lab’s maximum capacity. This can be expanded or adapted over time, with additional lab equipment or adding further LINQ modules.

The cloud-based Automata LINQ software seamlessly connects each activity in the ELISA workflow, providing full barcode scanning traceability for each sample, and adding test data to the lab’s LIMS system.

Explore other assays we can automate

Cell-based assays

Automate complex compound testing with one system capable of executing multiple cell-based assays for enhanced data collection and more.

High throughput screening

Our system, designed with high throughput screening in mind, automates complex compound screens with multiple analytic readouts and fewer errors.

Some of our clients

ELISA resources

Discover the frequent mistakes made during manual ELISA assays and how automation…

Read more Common Errors in Manual ELISA Assays – Automata

Find out how open, integrated automation can accelerate the ELISA development process…

Read more Scaling up ELISA development with automation

Find out how open, integrated automation can accelerate the ELISA validation process…

Read more ELISA assay validation: how automation can helpIs Automata right for my ELISA lab?

Liconic microplate hotel, Thermo Fisher Cytomat Microplate Incubators, SPT Labtech Firefly Liquid handlers, Certus Flex dispensers, Tecan Hydrospeed Microplate washers, BMG Pherastar Microplate readers, Azenta A4s and xPeel Microplate sealers and peelers, Barcode scanners, Automata LINQ bench and software, Automata Scara Robots.

This solution above has a capacity of 530 microplates a day, with an output of at least 78 samples p/m² / 7 samples p/ft².

Ultimately, the top-end capacity is mostly limited by space and system bottlenecks and can be expanded or shrunk as part of the development process with your lab.

We can create solutions for workflows that can start with integrating laboratory equipment-specific workflow steps as a workcell (like sealing and peeling plates, to washing) to reduce manual steps and time.

We can integrate multiple workcells together to combine entire workflows depending on the needs of your lab.

The journey to fully automated labs takes time, so we can start wherever you are in your automation journey. We can always adapt our platform layouts to new instruments you acquire as your needs change.

Yes. The Automata LINQ platform is vendor agnostic, so we can integrate third-party devices and software based on your needs and the problems your lab is trying to solve with the ELISA assay.

Sometimes ELISA systems can be restricted by incubation time requirements, washing and immunostaining requirements and shift availabilities. The Automata system doesn’t necessarily work faster than a person, but through being able to tend to multiple machines concurrently and enabling complete hands-off time, the system can run independently of human interactions, and your lab can increase throughputs.

Speak to us. Whether you are running Direct ELISA, Indirect ELISA, Sandwich ELISA or Competitive ELISA, there will always be steps in the workflow that can be optimised.

Our approach – called open, integrated lab automation – allows ELISA workflows to be automated end to end.

We do this by utilising both robotic and digital connectivity, facilitated by a smart lab bench and lab orchestration software.

We’ve automated ELISA workflows for several customers with a variety of different equipment and methods; the LINQ system is fully flexible, making automating ELISA easy.

Whether you are running Direct ELISA, Indirect ELISA, Sandwich ELISA or Competitive ELISA, there will always be steps in the workflow that can be optimised.

Automating your ELISA workflow will bring human, quality, and lab productivity benefits.

It can allow you to:

- Increase sample throughput, collect more data, and deliver the results you need at scale.

- Empower your people to focus on higher-value tasks by giving them true walkway time.

- Eliminate repetitive manual steps and the chance of manual errors.

- Increase your ability for auditing and quality control, enabled by better data quality.

- Discover and sold bottlenecks quickly to reduce lab downtime.

An immunoassay is an on-site or in-lab biochemical test that measures the presence or concentration of a macromolecule in a solution through the use of antibodies or antigens.

ELISA, or enzyme-linked immunosorbent assay, is a type of immunoassay.

An automated immunoassay is simply an immunoassay that is executed using some kind of machine-based automation.

Automation could be benchtop – for example having a robot pipetting rather than a human – or end-to-end, which would see digital and robotic connections used to conduct the majority of the immunoassay with minimal human intervention.

Automating immunoassays offers many benefits to labs and scientists.

Having full workflows automated and requiring little human intervention gives highly trained scientists more walkway, allowing time for analysis and innovation.

Reducing human interactions also improves the repeatability and consistency of experiments and results, removes the risk of human error and contamination, and allows better traceability.

Automating immunoassays is the best way to scale throughput and lab productivity without investing in additional space or headcount.