In this guide, you`ll find out:

Overview

A virology contract research organisation (CRO) worked with Automata to take its lab automation to the next level by fully automating its ELISA process. Automata’s partnership will result in a reduction in manual interactions, a substantial increase in throughput, and associated cost savings.

The brief

The CRO needed to scale up their service due to increasing demand from the biopharmaceutical community. To boost throughput without needing substantial increases in staffing levels, which could have a detrimental impact on quality, the CRO approached Automata to discuss fully automating their ELISA process.

Automata were asked to design a single automated ELISA process, optimised for their most frequent assays, that would:

- Improve utilisation of the CRO team

- Bring scale on a global level

- Increase quality and reproducibility

- Increase throughput

- Fit into the lab space available

- Maintain uptime and allow global servicing

The challenge

Data integrity and contamination risk were key factors for this solution.

Part of the CRO’s work involves virology testing for clinical trials. The critical importance of this work meant that data integrity was a key factor for their ELISA process. It was vital that the process was robust, avoided contamination, and was orchestrated by software with built-in redundancy.

Due to the cutting-edge nature of the work, integration of the right equipment was essential to achieve the required throughput while minimising the risk of contamination. Automata worked closely with the CRO to make sure the solution met these goals.

Automata's solution

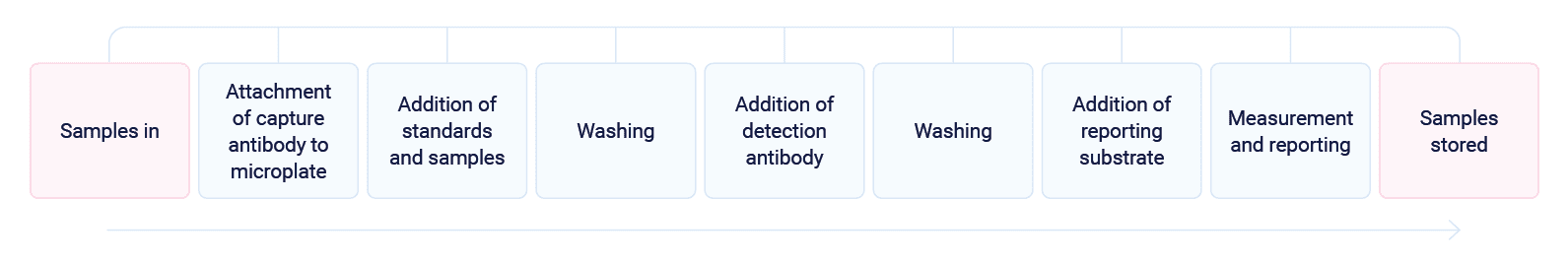

Automata worked with the CRO to design a fully automated ELISA system, which maximised throughput, provided robust data management, and significantly reduced manual interaction

Automata is a lab automation platform that combines specialised lab benches with open, integrated orchestration software. This turns labour-intensive workflows into streamlined automated systems, providing true ‘walkaway’ time for staff. Automata’s solutions are achieved through combined robotic and digital integration of multiple devices, many of which a lab may already have.

Automata worked with the CRO to review their specific protocols and build their manual procedures into an automated workflow. The new workflow aimed to improve efficiency and enable automation.

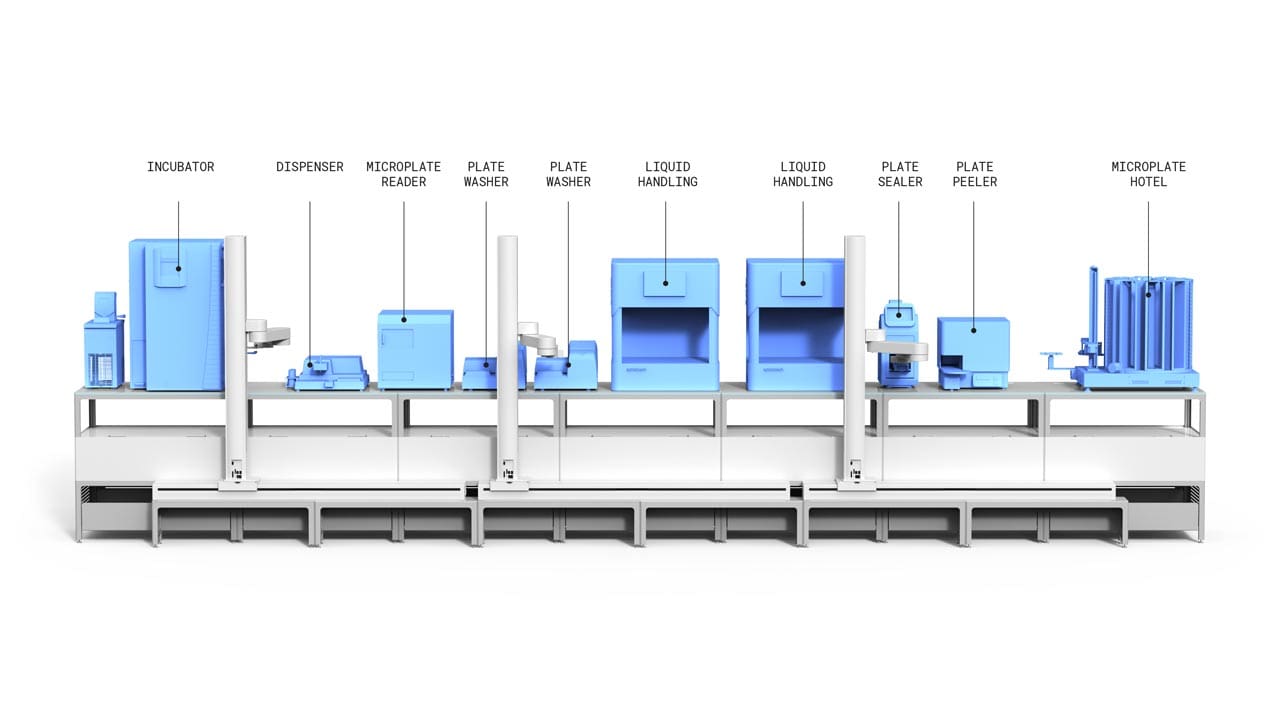

Built on the Automata LINQ robotic lab bench, the new ELISA system could be expanded or adapted over time, with the addition of new lab equipment, or by adding further LINQ modules.

Automata’s cloud-based laboratory orchestrator was used to provide a software platform that seamlessly connected each activity in the ELISA workflow, providing full traceability for each sample, and adding test data to the lab’s LIMS. Barcode scanners on each LINQ module and within the instruments themselves provided tracking for each sample, right down to its position within each microplate.

With each piece of equipment able to operate concurrently, the CRO was able to parallelise activity, maximising capacity.

The following equipment was integrated into the system:

- Microplate hotel

- Microplate incubators

- Liquid handlers

- Microplate washers

- Microplate readers

- Microplate sealers and peelers

- Barcode scanners

- Automata LINQ modules

- Automata Scara Robots

Estimated impact

Based on the final solution that will be installed, the new, fully automated process is expected to achieve:

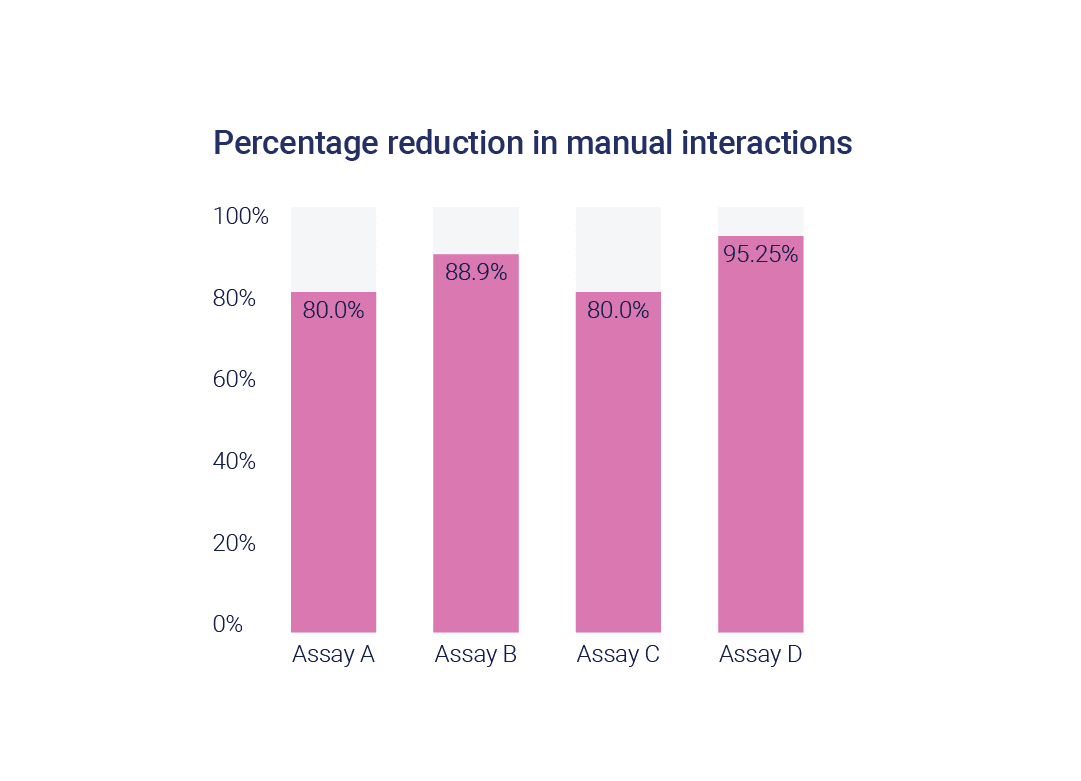

An 80–95.25% reduction in manual interaction

A throughput of up to 530 microplates per day

Reduced risk of manual errors

Increased data quality as all actions will be fully traceable