Article contributors: Daniel R Leonce¹, Ashley S Fowler¹, Vladimir Khon², Alice Tome-Fernandez², Vicky Dearing¹, Emma Norris², Jerome Nicod¹

¹ Advanced Sequencing Facility, The Francis Crick Institute, London, UK

² Automata Technologies Limited, London, UK

Introduction

Automation instruments are now a common feature of genomics labs, increasing experimental throughput, reproducibility, and resources optimisation. However, the scalability of automation is limited by the current approach of using benchtop instruments as standalone units. Collaborating with Automata, we have leveraged their LINQ platform to establish full walkaway genomics workflows by integrating our existing instrumentation. This automation initiative has significantly increased our facility’s capacity. It has liberated our scientists to focus on more demanding projects and will enable us to run extended workflows overnight, ensuring instrument availability during the day.

Reaching the limits of automation

The prevailing use of automation still requires an operator to be present at multiple steps during an experiment, typically for samples transfer between devices. Each instrument is treated independently, with the scientist or technician acting as the crucial link between them, thereby impeding workflow scalability. This methodology presents several drawbacks: Firstly, it confines highly skilled scientists to repetitive tasks. Secondly, each manual step introduces the risk of errors. Lastly, the use of costly equipment is restricted to standard working hours. Adopting an integrated automation approach circumvents these challenges, enabling the realisation of the complete capabilities of laboratory equipment.

The opportunity

The Advanced Sequencing Facility (ASF) at the Francis Crick Institute delivers comprehensive genomics support, ranging from standard high throughput sequencing to cutting-edge technology applications. While our scientists invest considerable time in R&D projects, our laboratory must also maintain efficient service delivery. To streamline our workload and reclaim valuable time, we collaborated with Automata to identify and fully automate routine workflows using their LINQ platform. This initiative saw the integration of 8 of our existing instruments into the system, facilitating the automation of a wide range of methods. While the system programming is overseen by our automation specialist using dedicated software, any trained member of our laboratory can execute the workflows.

Top Panel: Traditional lab equipment usage relies on operator presence throughout each process step.

Bottom Panel: Schematic representation of the LINQ platform installed at the Crick.

Comprising 6 Automata workcells, it integrates & devices: Hamilton STAR, SPT Labtech Dragonfly, thermocycler, centrifuge, plate sealer and peeler, plate reader, and qPCR machine (note: SPT Labtech mosquito pending installation). This platform enables the programming, setup, and execution of complex workflows devoid of manual intervention.

Automata X Crick partnership (est. 2021)

May 2022

June 2023

Automata and the Advanced Sequencing Facility have been working in partnership since 2021. An early prototype system featuring Eva arms was installed in the ASF in 2022, with Crick scientists and Automata engineers working together to develop what has become the current LINQ platform. This ongoing collaboration persists in the design and implementation of new workflows.

Key features of Automata LINQ platform

Open

The platform’s open architecture allows instruments to function independently or as part of integrated workflows

Compact

Although densely packed with instruments, the platform has a small footprint, making it suitable for standard lab space

Flexible

New workflows can be designed on the building software using already integrated equipment

Scalable

The platform is manufacturer-agnostic, and additional instruments can be added to increase capabilities and throughput

Fully automated workflows

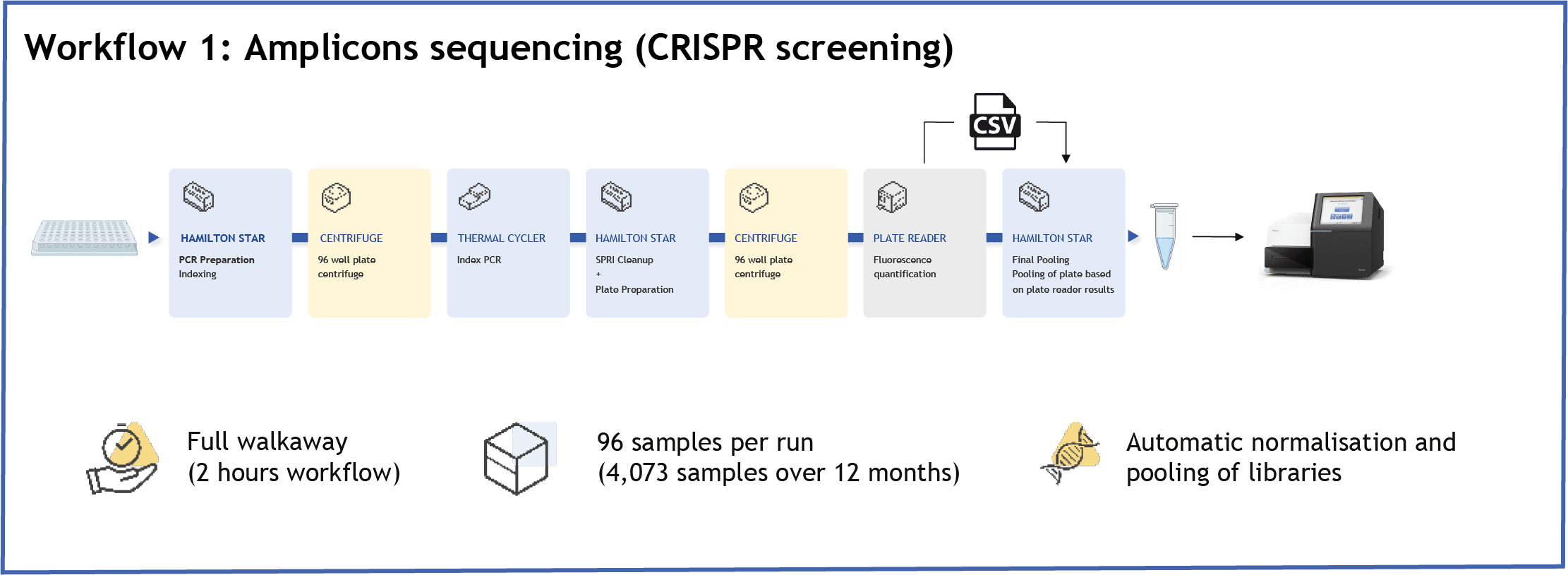

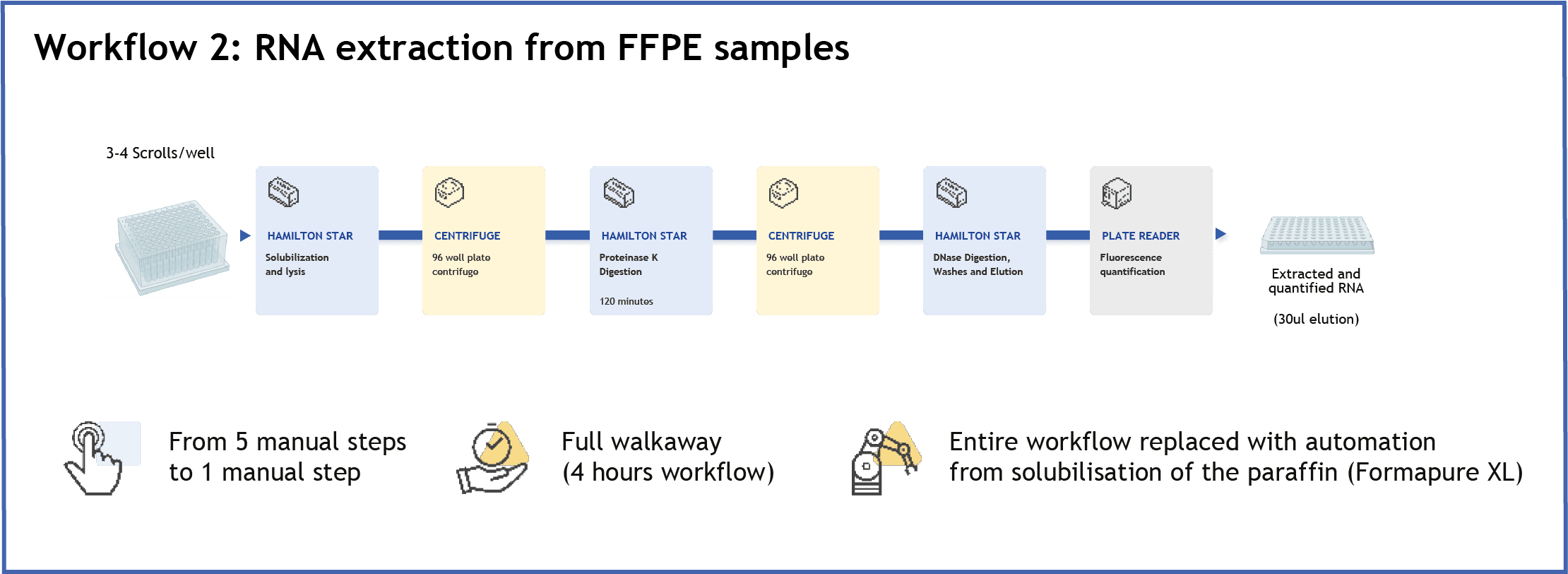

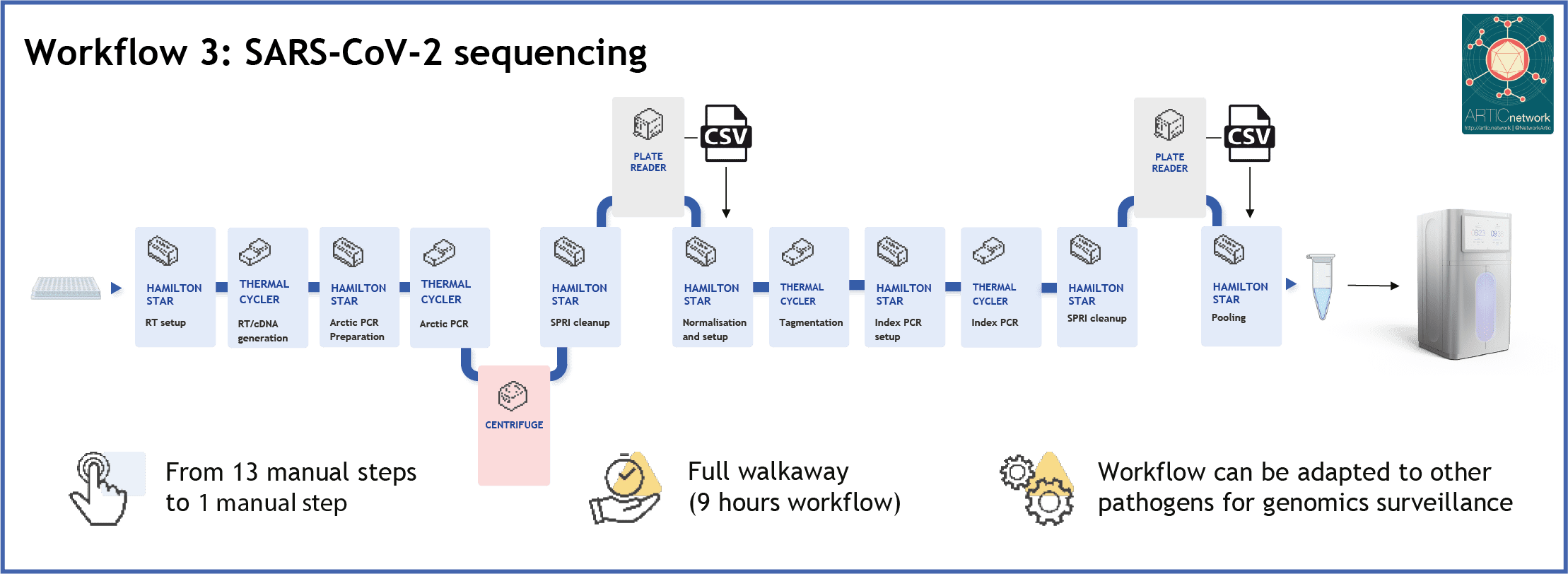

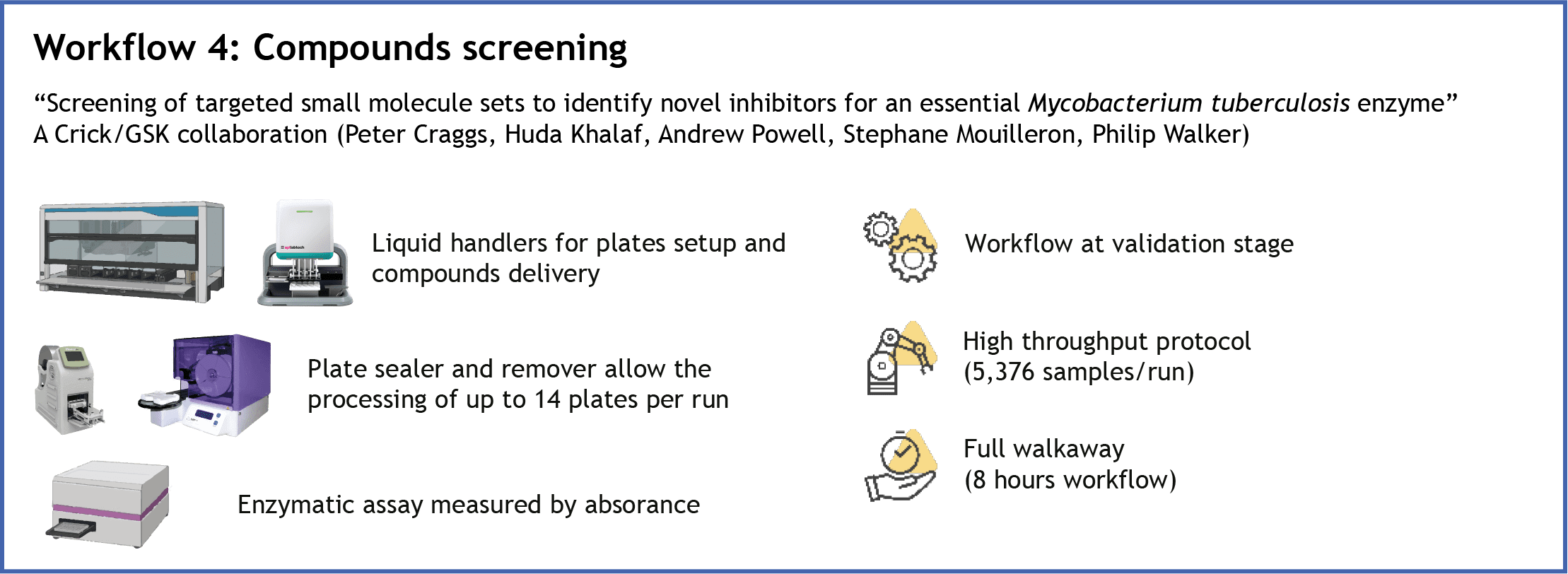

The boxes below describe the workflows that have been implemented on our LINQ platform. All are full walkaway protocols, necessitating only 30-45 minutes of setup time and requiring no further manual intervention until completion 2-9 hours later. Future plans include the full automation of large-scale qPCR experiments, single-cell FLASH-seq protocol and a miniaturised workflow for the genomic characterisation of genetically modified early embryos (UKRI-funded project).

Thinking beyond the benchtop instruments

Explore how automation is transforming key genomics workflows, from CRISPR to COVID-19 and cancer research