Reducing human interaction in ELISA

How Automata worked with a UK-based CRO to reduce human steps and scale throughput with a fully automated ELISA workflow

The brief

Automata needed to provide an automated ELISA system capable of running 110 microplates per 8-hour shift, while minimising manual interactions.

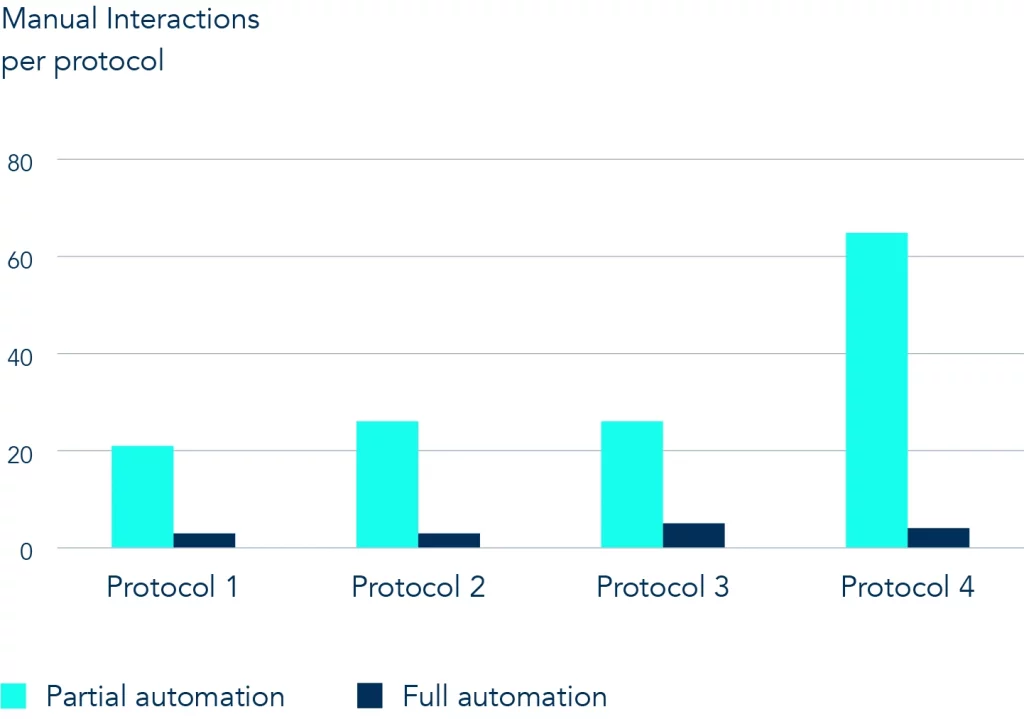

For the past 7 years, the CRO lab has been developing immunoassays for Biopharmaceutical companies. During this time it has relied on a partially-automated system of liquid handlers, reagent dispensers and plate washers, with lab technicians moving ELISA plates between processes.

However, the number of manual steps involved meant that the lab was limited in throughput with its existing team. As a result, the CRO wanted to add greater automation in the ELISA process to reduce these manual interactions with their instrumentation. With more automated workflows, the current team was able to focus on assay development as opposed to spending significant amounts of their valuable time moving microplates.

Since future-proofing their set up was a priority for the lab, it was important that the automated system they used would grow and develop as their clients’ needs evolved. This required:

- A solution with in-built flexibility, allowing the CRO to reprogram the automated system when needed

- A solution that was able to scale capacity over time

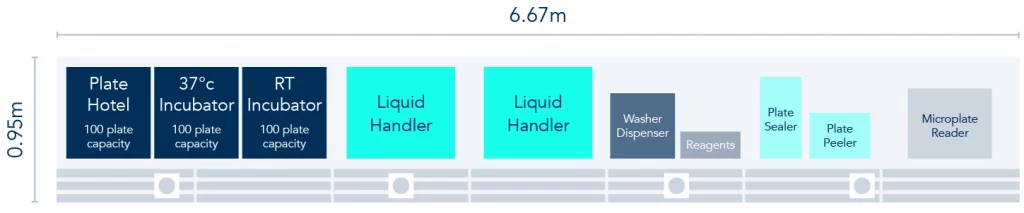

- A system that was able to fit within their existing lab space, with minimal disruption to day-to-day operations

The challenge: Finding an automation solution that was both flexible and scalable

The CRO had been looking to automate their ELISA process for two years before interacting with Automata. However, they had not been able to find a vendor capable of providing a solution that fit their requirements.

Traditional systems integrators were unable to provide a solution that was sufficiently flexible to grow with their evolving needs. Meanwhile, liquid handling platforms were unable to automate the full workflow. In addition, given their low throughput, these liquid handling solutions also took up too much space to be considered feasible options at scale.

Automata’s solution

Automata worked with the CRO to review their specific protocols in order to build their manual SOPs into an automated workflow. Working with the lab’s Senior Scientists, Automata optimised the CRO’s workflows for automated processing, and, through joint validation, they were able to remove the unnecessary steps that lab workers had added to the SOP over time.

Optimising throughput, while accommodating the CRO’s existing system, was the key to delivering a project that met the scale ambitions of the CRO.

Built on the Automata Labs Robotic Lab Bench, the fully automated ELISA system could be expanded over time to include new lab equipment (adapting to required capabilities) or by adding further equipment (further scaling capacity).

The following equipment was integrated into the system:

- Plate Hotel

- Plate Incubator (37 degrees)

- Plate Incubator (4 degrees)

- Liquid Handler

- Automated Plate Sealer

- Automated Plate Sealer Remover

- Plate Washer

- Reagent Dispenser

With each piece of equipment able to operate concurrently, the CRO was able to parallelise activity, maximising the capacity of each system, achieving a far higher throughput than standalone liquid handling systems.

The automated equipment was operated using Automata Labs Designer, a single platform that integrated with all the equipment and allowed lab workers to design, develop and validate protocols. This offered the lab:

- Python programming of workflows for complete control

- A simple drag and drop graphical user interface for common tasks

- Best practice tools for reviewing, revisioning, and pushing protocols through git version tracking system.

- Push method statements to multiple independent instruments or systems at once

- The ability to collaborate with and give progress updates to research scientists, lab technicians, and lab managers in one place.

The impact

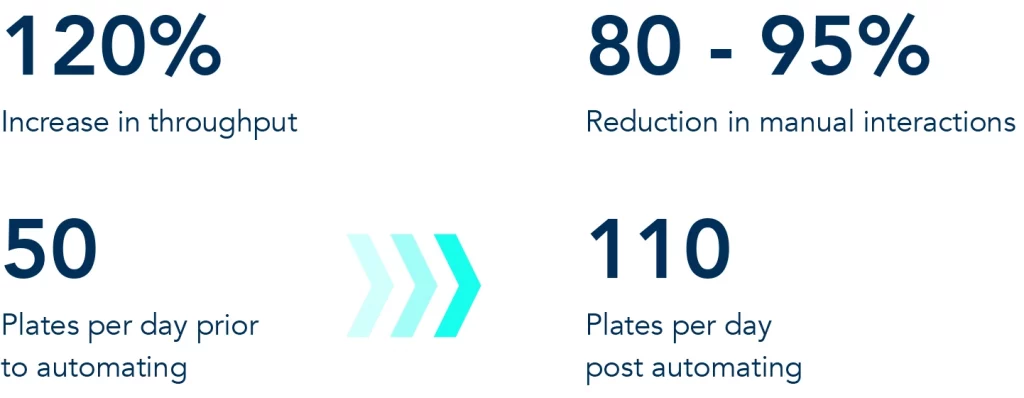

The impact of end-to-end automation of the ELISA process was significant:

- New clients: scaling from 50 to 110 plates per day allowed the CRO to grow their business with new and existing clients, without having to hire additional staff

- Staff retention with repetitive processes reduced and replaced with more meaningful work, retention of the existing team improved

- The lab could utilise machine learning systems – with automation improving the quality and quantity of data, the CRO was able to to invest in machine learning platforms to analyse the data output

- Reduced human error – reducing the number of manual steps limited the impact of human error on the ELISA process, resulting in more reliable results

Ready to Scale Up Your Lab’s Efficiency?

Unlock seamless, scalable automation with LINQ, connecting instruments and workflows to adapt as your lab grows.