In this guide, you`ll find out:

Overview

A UK-based lab that provides genomic testing for infectious diseases worked with Automata to take its lab automation to the next level by automating the bottleneck in their workflow. Automata’s solution will result in a significant reduction in manual interactions, allowing staff to focus on other activities.

The brief

The lab had previously used automated systems for their genomic testing workflow. However, when they made the decision to reduce reagent costs by changing their DNA library preparation process to use 384-well microplates rather than 96-well microplates, they found that the existing system was not sufficiently flexible.

Staff now had to manually move plates from one piece of equipment to another during library preparation, and this had a detrimental effect on both throughput and walkaway time.

Automata was asked to provide an automated library preparation system capable of handling 384-well microplates, in order to streamline the genomic testing process and provide the capacity for upscaling.

It was important that traceability was maintained for the whole process, and that this data was exported to LIMS.

The challenge

The current library preparation process required significant manual interaction throughout the day, and a key requirement was to fully automate the process, freeing up lab staff to work on more value-added activities.

Automata's solution

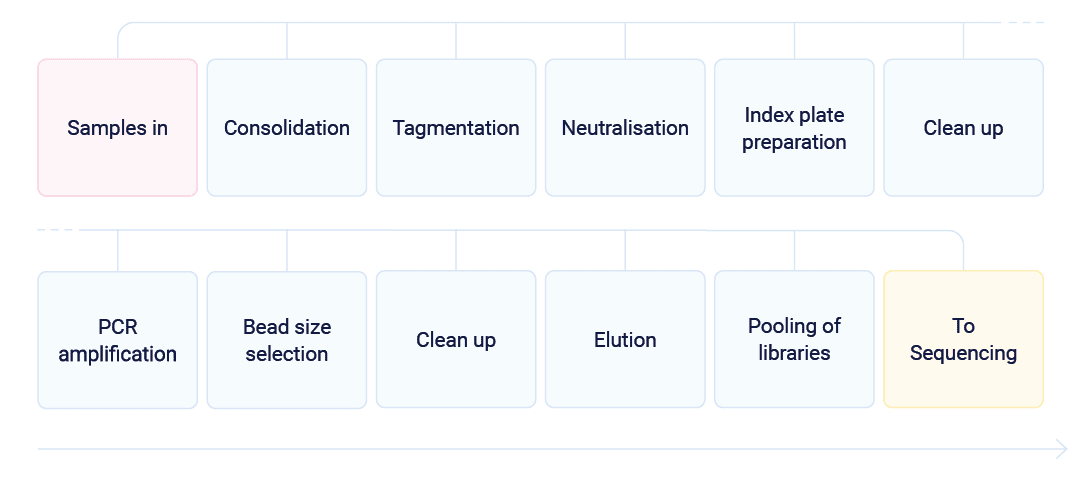

Automata worked with the lab to design an automated DNA library preparation system which would slot in-between their existing automated processes

Automata is a lab automation platform that combines specialised lab benches with open, integrated orchestration software. This turns labour-intensive workflows into streamlined automated systems, providing true ‘walkaway’ time for staff. Automata’s solutions are achieved through combined robotic and digital integration of multiple devices, many of which a lab may already have.

Built on the Automata LINQ robotic lab bench, the automated library preparation system could be expanded or adapted over time, with the addition of new lab equipment, or by adding further LINQ modules.

Automata’s cloud-based laboratory orchestrator was used to provide a software platform that seamlessly connected each activity in the library prep workflow, providing full traceability for each sample, and entering test data into the lab’s LIMS.

With a piece of equipment able to operate concurrently, the lab was able to parallelise activity, maximising the capacity of each system.

The following equipment was integrated into the system:

- Microplate shaker

- Microplate vortex

- Microplate reader

- Liquid handlers

- Magnetic bead separation block

- Cooling block

- Microplate incubator

- Microplate sealer

- Microplate peeler

- Microplate centrifuge

- Thermocycler

- Automata LINQ modules

- Automata Scara Robots

Ready to Scale Up Your Lab’s Efficiency?

Unlock seamless, scalable automation with LINQ, connecting instruments and workflows to adapt as your lab grows.

Estimated impact

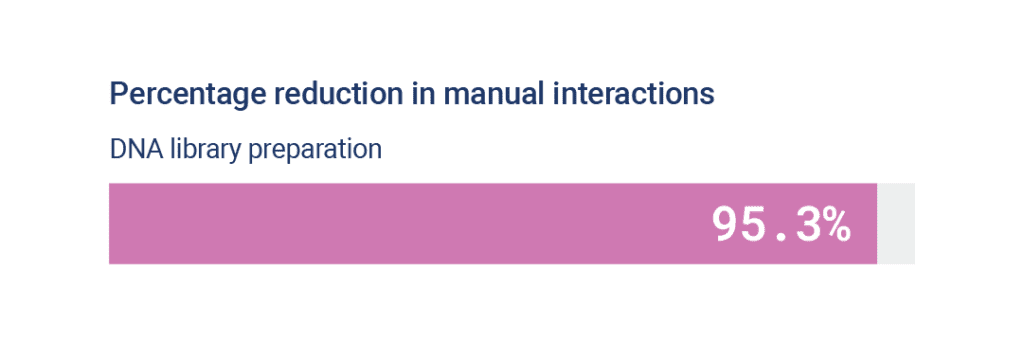

Based on the final solution that will be installed, the new, fully automated library preparation process is expected to achieve:

95% reduction in manual interaction

Reduced risk of manual errors

Increased data quality as all actions will be fully traceable

*The lab first engaged with Automata in Q3 of 2022, and the final system is due to be installed in Q3 of 2023, an end-to-end process of about one year.