The life sciences industry has witnessed significant advancements in recent years, with automation emerging as a transformative force in laboratories. However, the journey toward widespread adoption has its challenges.

This four-blog series will delve into the intricacies of integrating automation into the heart of pharmaceutical research and development labs, from flexibility and usability to integrating data and improving error handling.

The third in our series focuses on flexibility in lab automation and how a new approach to automation development will put scientists back in control.

Skip to:

While life science labs are at various stages of their automation journey, most now consider it a normal part of life. For advanced labs, though, automation is the key to continued and future success.

In drug discovery, automation can speed up complicated processes end-to-end to give faster patient results and, ultimately, a competitive advantage to the business.

Even with such clear benefits, some platforms still don’t have one of the key features an ever-changing sector like pharmaceuticals needs: flexibility.

The challenge

Why flexibility in lab automation platforms is a challenge is no secret; any time you try to build something to serve all people in all ways, it’s hard.

In life sciences, the variables that automation developers have to consider are some of the most complicated to tackle:

- Every lab employs multiple vendors across instruments, consumables, databases and software – and there’s little standardisation across suppliers

- Each lab has different measures of success – accuracy rates, turnaround time, and equipment up/down time; the KPIs are endless

- Geography plays a part, with different countries and specific sectors having laws and regulations across multiple stages of the drug development process

- Labs focus on different types of science employing different assays

- Assays themselves differ from lab to lab

- Space is a real consideration – we have a lack of space in the UK, whereas there is no such issue in other markets

We could go on. The point is that these nuances mean the word ‘flexible’ becomes infinitely more important when designing lab automation solutions but intrinsically much harder to do.

Julie Huxley-Jones of GSK put it best when she said:

New automation principles are needed

Automata developed a lab automation platform on a principle we’ve dubbed ‘open, integrated automation’. We lead with this ethos for precisely the reasons outlined above: the future of lab automation depends on flexibility. We don’t believe this can be achieved without developing open access, vendor-agnostic solutions.

Flexibility isn’t unachievable; it just needs a new approach.

Keep reading to understand more about flexibility in lab automation and how developers like us must respond to these challenges.

What flexible automation means for large organisations

Scale

Scaling up within pharmaceuticals can mean different things at different stages of the drug discovery and development cycle, but what we mean is ‘give me more’.

Whether that ‘more’ is time or throughput, physically in terms of samples or digitally on the side of data, we need to give labs the ability to grow.

To respond, automation needs to look at barriers and concerns first. In labs, these may be:

- A lack of space

- Inability to replace legacy systems

- Lack of knowledge or experience

- Vendor lock-in

- Cost

- Quality of output (results)

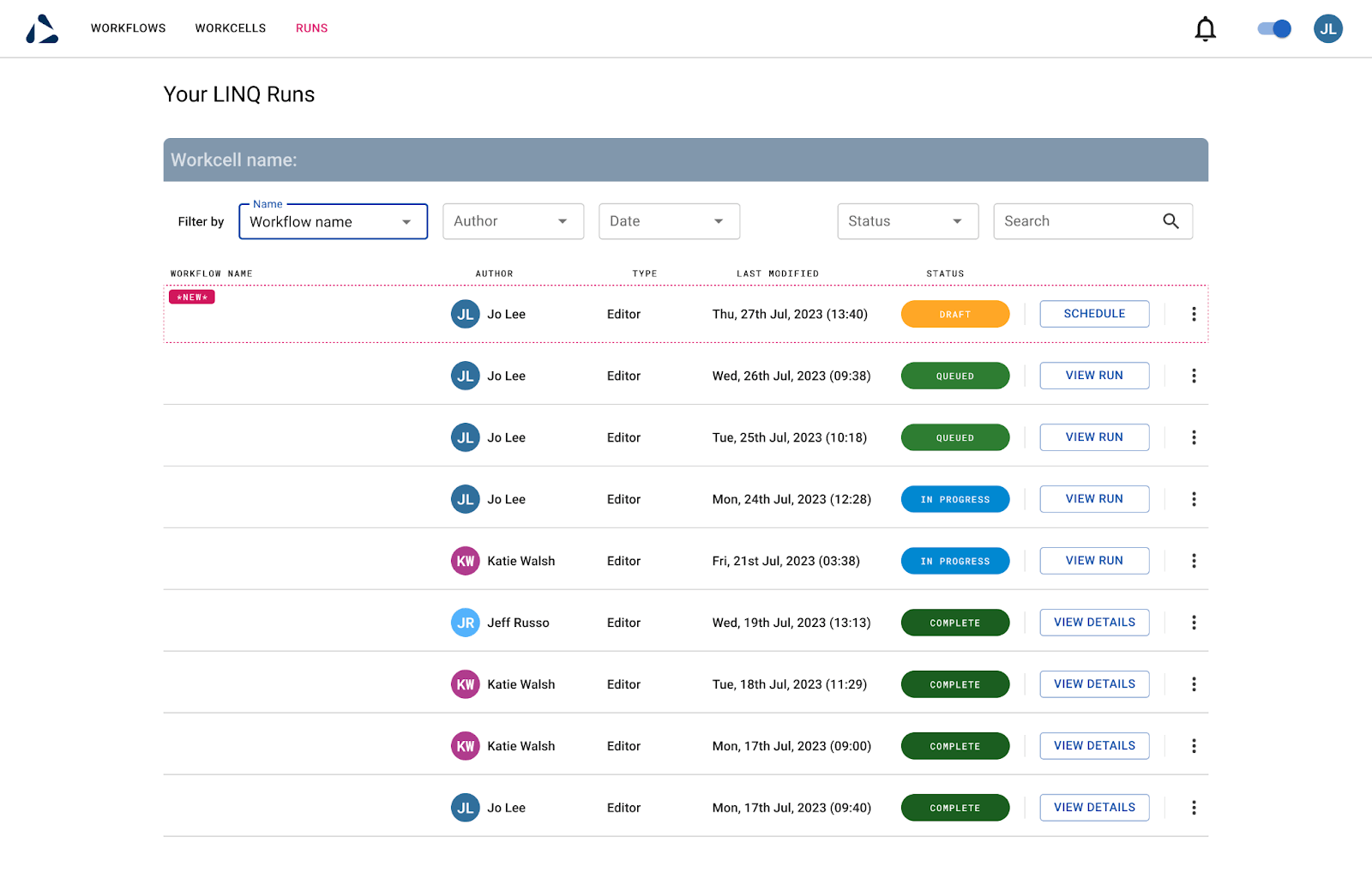

LINQ has been developed to overcome these barriers by creating a modular, reliable, easy-to-use automation experience.

Start with a small automated workcell system and then add components when you want to automate more actions or include new processes. You can expand this system in weeks, not months.

Responsiveness

Responsiveness can be about scale, but this truly means the flexibility to change anything fast.

The COVID-19 pandemic is, unfortunately, the perfect example of this and one of the reasons Automata turned to lab automation development in the first place. Within months, it became clear that a fast response from the pharmaceutical sector was critical to controlling it.

Though a pandemic is a worst-case scenario, changes in demand and needs happen constantly in this sector, and large-scale pharmaceutical labs can’t rebuild from scratch every time.

LINQ can automate without discrimination for any goal, allowing you to decide what you automate and when.

Instruments can be switched out, data collection criteria can be changed, workflows can be designed and tested, and LINQ can pull on resources from across an entire connected automation network to allow for reallocation should the need arise.

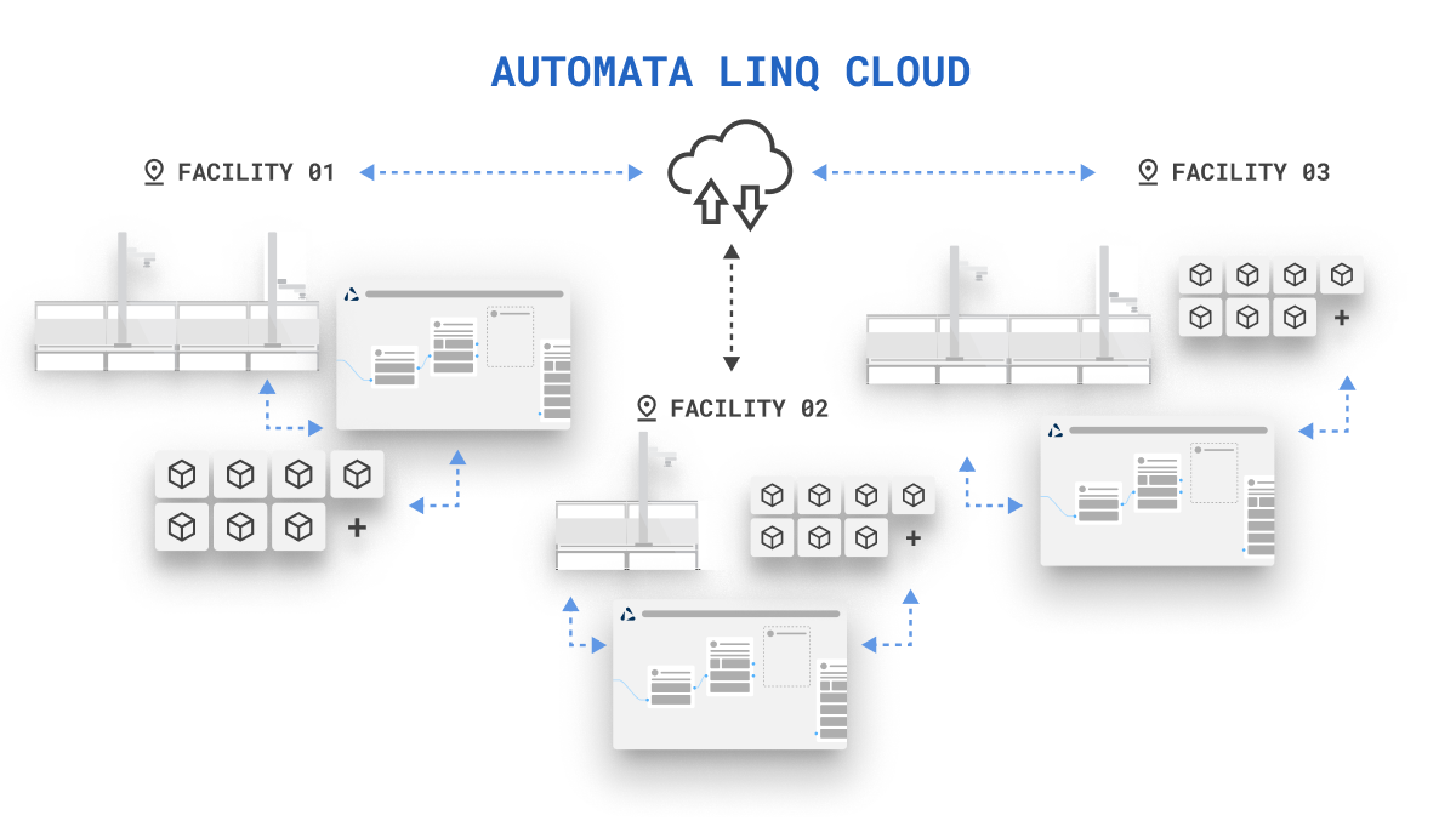

Where multiple LINQ systems are connected, users can pull on resources from across the automation infrastructure, so responding to changing demand and innovating is easy.

Facilitating innovation

The same flexibility issues as above apply to automation in an R&D setting, but the consequences are even more significant: we’re at risk of entering a world where technology restricts what people can achieve, stifling creativity and innovation.

Experimental design should be led by the need or hypothesis, not the capabilities or accessibilities of an automation system, or data.

This is true at both hardware and software levels: hardware needs to be interchangeable and able to handle any array of chemistries, consumables, and sample types, while software should cope with new modalities and remove data silos.

Data

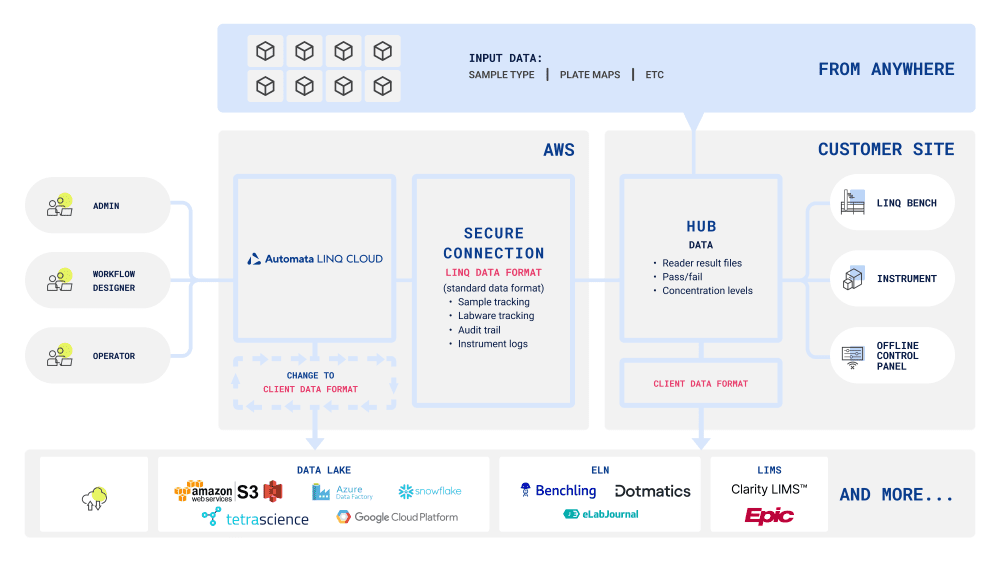

Data ecosystems in the labs of the future will be heterogeneous, so creating automation that has strict data handling parameters that can’t be changed won’t work. We need automation platforms to consider multiple data points and integrate with any data lake.

LINQ Cloud, the software component of the LINQ automation platform, can easily do this.

- It transfers data in real-time for full viability and multipoint analysis

- Adapts to multiple client data formats

- Delivers data to any repository

- Integrates with any LIMS

There are no data restrictions on input or output with LINQ, so as well as allowing flexibility within a known system, it’s also ready to transfer new types of data from AI resources whenever they become scientifically suitable.

Collaboration

Using pandemics as an example again, GSK issued a document detailing its position on pandemic preparedness in March 2022. In it, they point to collaboration as one of the underpinning principles:

Allowing access to the right information in a secure, measurable and traceable manner opens the door for much greater collaboration opportunities.

For internal collaboration, LINQ has 21 CFR-approved user management capabilities to promote confidence through secure access rules. You can set permissions at admin, creator and operator levels so everyone can see what they need to see.

And because information tracked on LINQ, like audit logs, is easily accessible and can be exported, information is readily available whenever needed.

Connectivity

The industry needs more connectivity across the board to support this kind of collaboration.

By connectivity, we mean:

- The ability to connect the instrument data flows to data lakes

- The option to see the status of equipment easily

- Systems that allow interventions both digitally and physically from robot technology and software like orchestrators and schedulers. End-to-end workflow automation isn’t possible without this

- At a network level, multiple automated workcells need to communicate with a central platform and each other for real flexibility in resourcing and data collection

- Cloud connectivity should support centralised knowledge sharing and remote error handling

Everything integrated on the LINQ platform is connected, from instruments to data to users.

- LINQ Cloud communicates run instructions to the platform and integrated instruments, and it pulls information back from those elements into your data lake

- Anyone with user permissions can access LINQ Cloud online so global teams can utilise one source of truth

- Scara robot arms and a magnetic transport superhighway connect instruments and samples, and those actions are driven by a scheduling engine that bridges the physical and digital worlds

The flexibility challenge will only worsen as AI introduces more data, our population becomes increasingly diverse, and new lab tech continues to launch. Automation can step up to this challenge; we just need to listen to what scientists tell us and work on building OUT all the restrictions we previously built IN.

Put the power back in the hands of scientists by seeking solutions built with those open, integrated automation principles like Automata. Get in touch to explore LINQ today.

Read the other blogs in the series

How can lab automation help ensure that the data we generate now…

Read more Data & Reproducibility: Single Source Of Truth In The Lab

Why is lab automation so hard to use? And why does it…

Read more Balancing usability and functionality

Discover how automation platforms like LINQ handle errors to improve trust and…

Read more Making error handling better