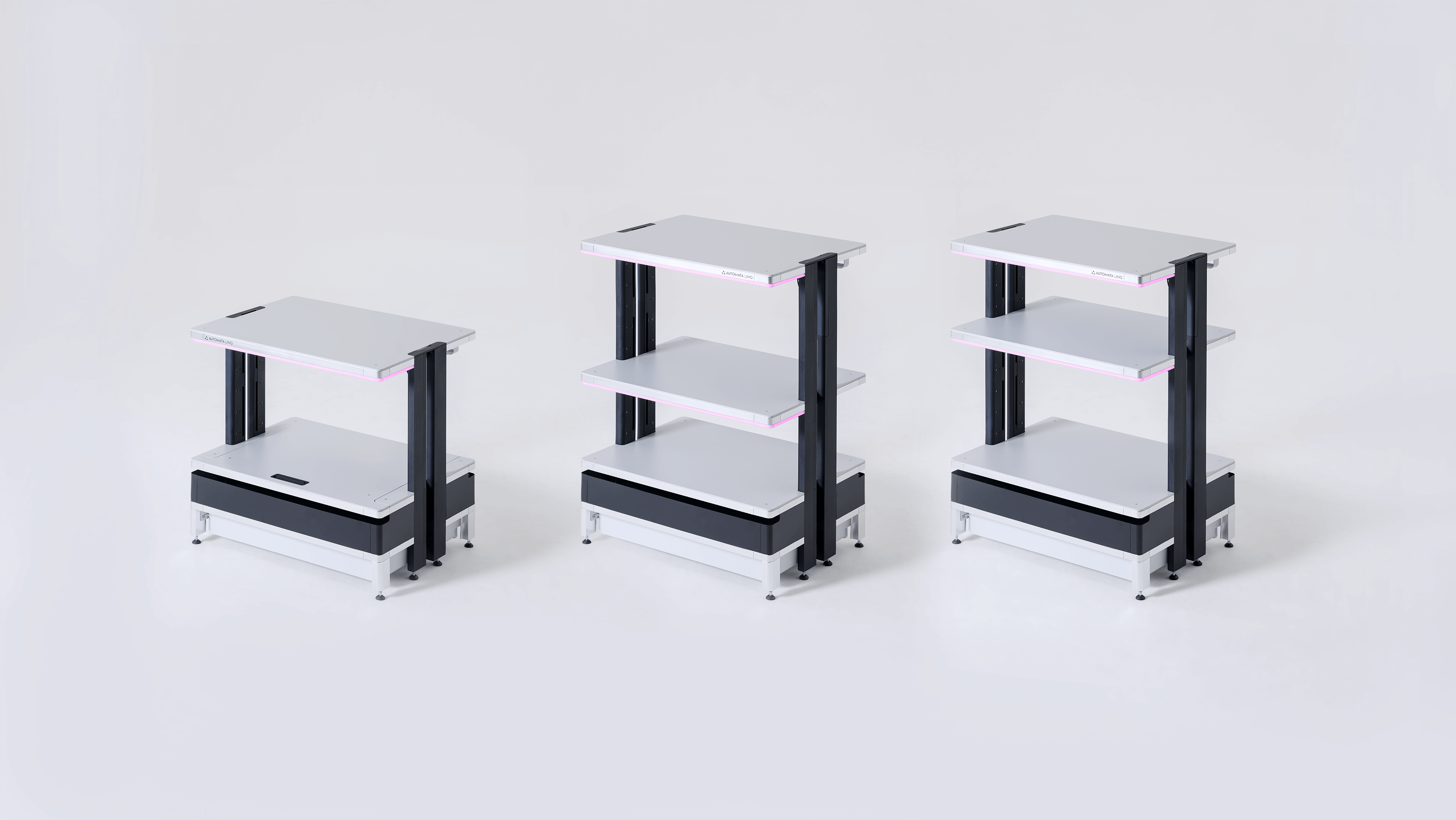

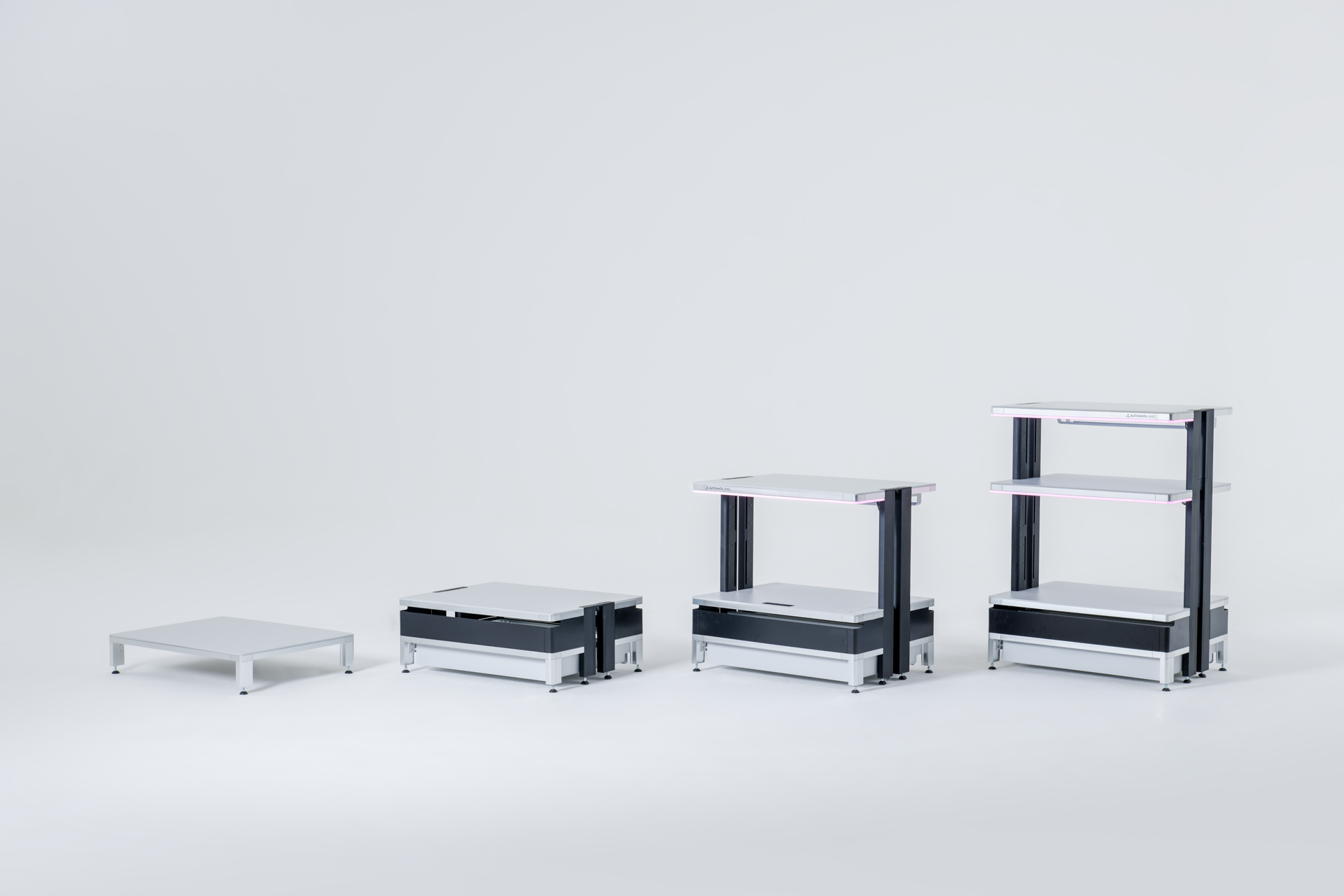

A configurable, expandable and future-ready hardware platform

Build workcells that...

Without any additional footprint

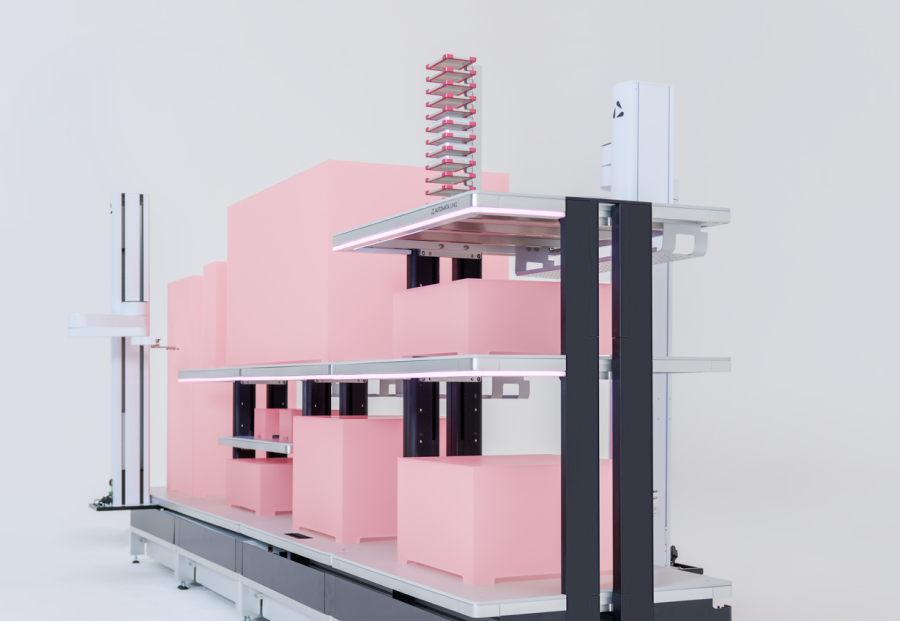

Vertical rack system

Allows for higher instrument density per footprint

Vertical worktop freedom

Ability to place worktops in multiple vertical positions

A variety of different configurations

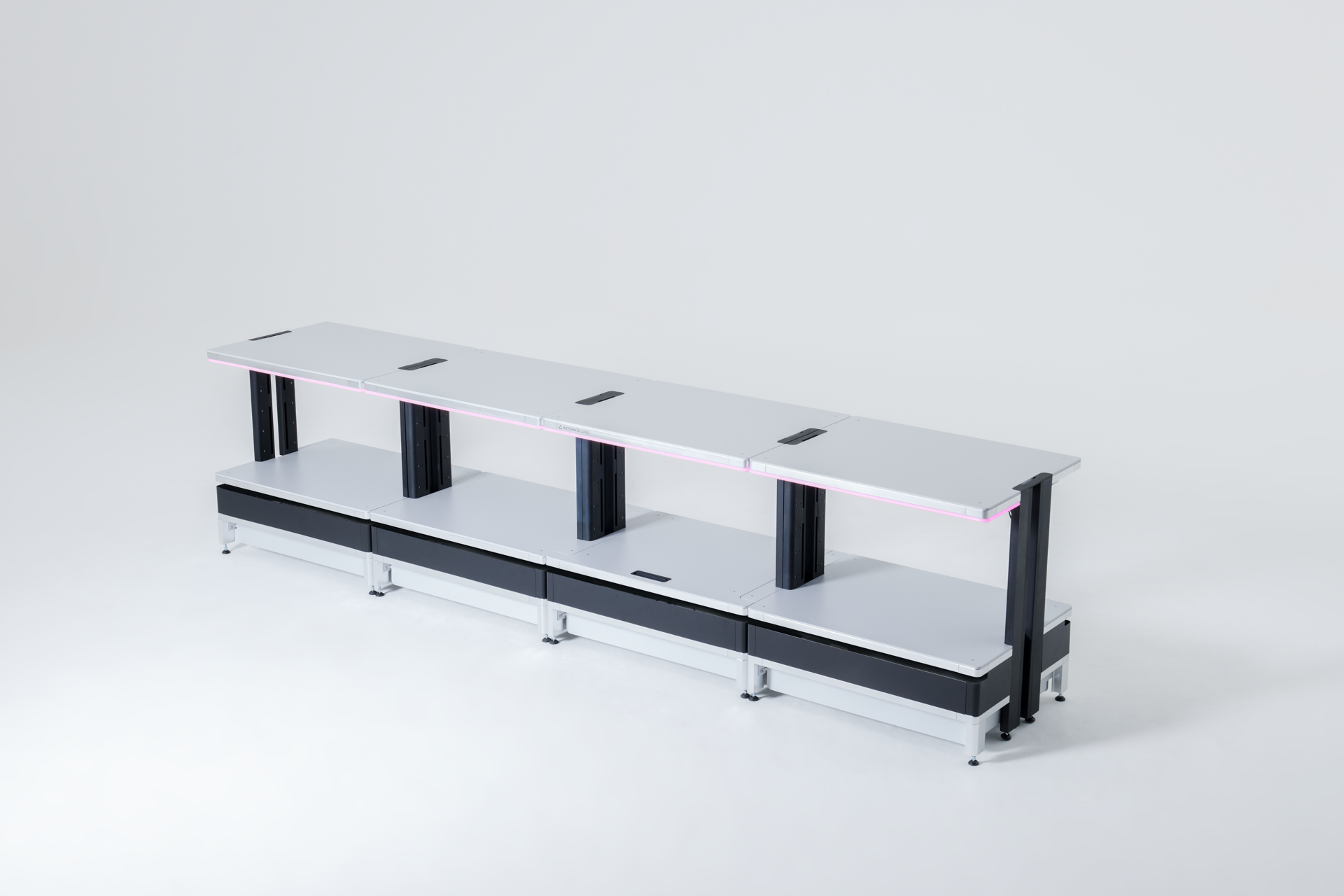

Linear

Connect LINQ Bench units in a straight line with 2 or more units.

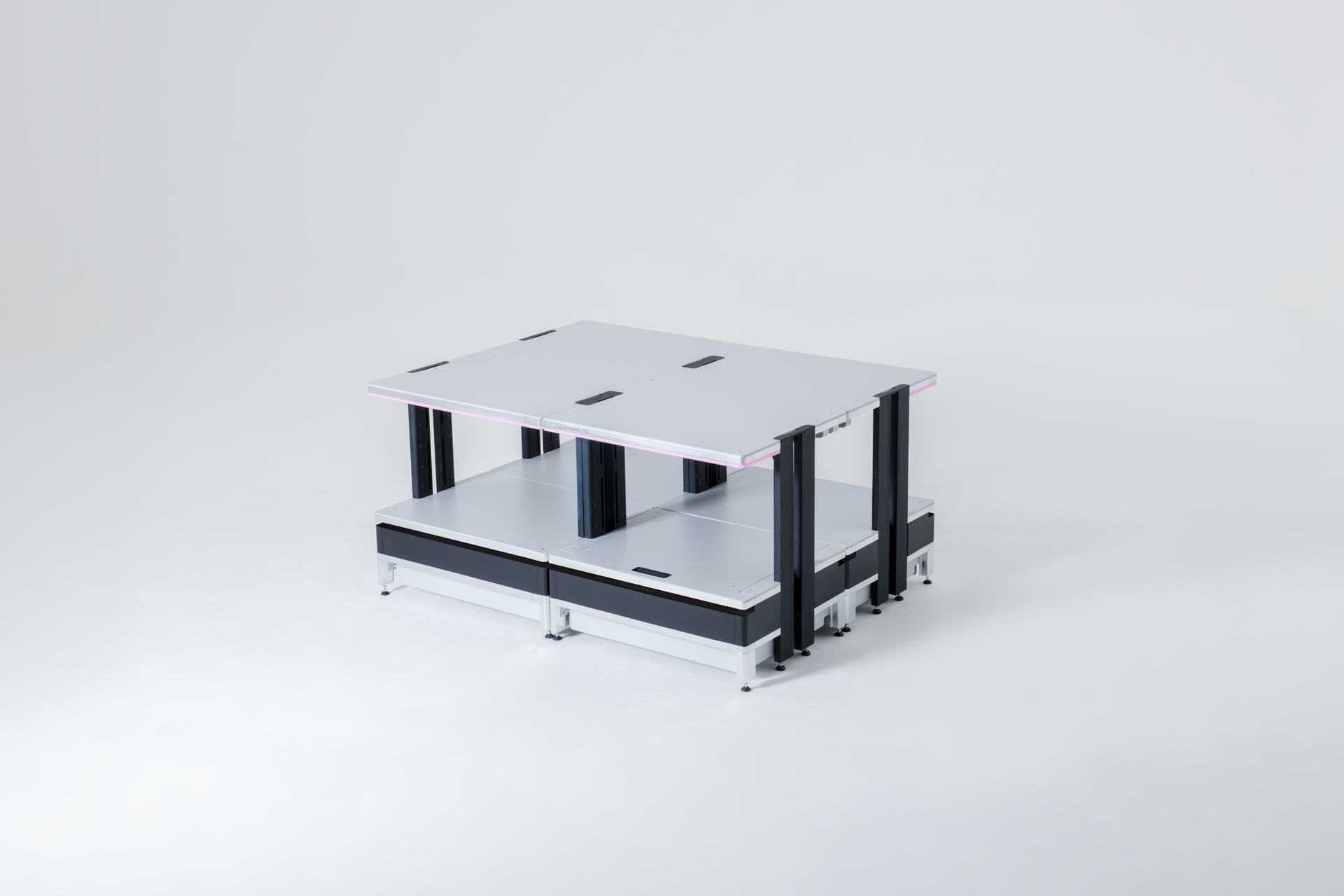

Island

Connect LINQ Bench units back-to-back or side-by-side to form a flexible island setup—no symmetry needed.

Interior Corners

Connect linear Bench units around interior corners using identical units.

Exterior Corners

Connect linear bench units around exterior corners using uniform units.

Freedom to choose, flexibility to scale

LINQ's instrument-agnostic Bench gives labs complete flexibility to choose, integrate, and scale equipment from any manufacturer—no compatibility issues, vendor lock-in, or reliance on costly proprietary supplies. With seamless connectivity, enhanced efficiency, and future-ready adaptability, labs can optimize workflows and easily adopt the latest technology as they grow.

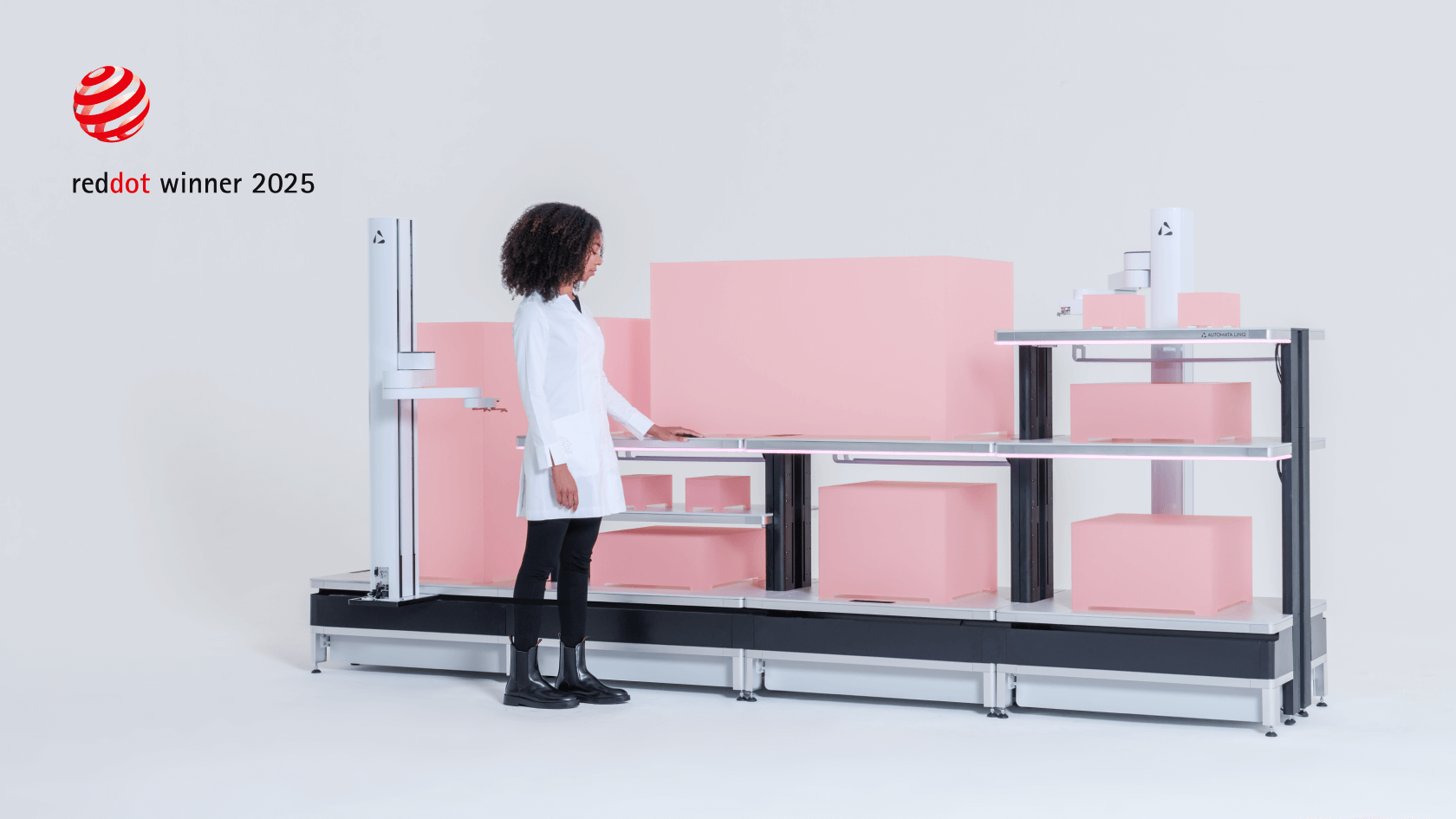

Future proof and easily expanded

Rapidly scale your lab— add new equipment by expanding the bench. As your needs grow, boost throughput by integrating robotic arms, plate transport layers, and more, all within the same consistent footprint and do so within a short time period.

While making it easier to access instruments in all locations

Turntable

Switch between manual and automated modes, as well as improve instrument access.

Slider

Improved usability for access to instruments for consumables replacement and servicing.

Stacking Modules

Increased density of small and medium sized instruments as well as a variety of consumables.

Transport options matched to throughput needs

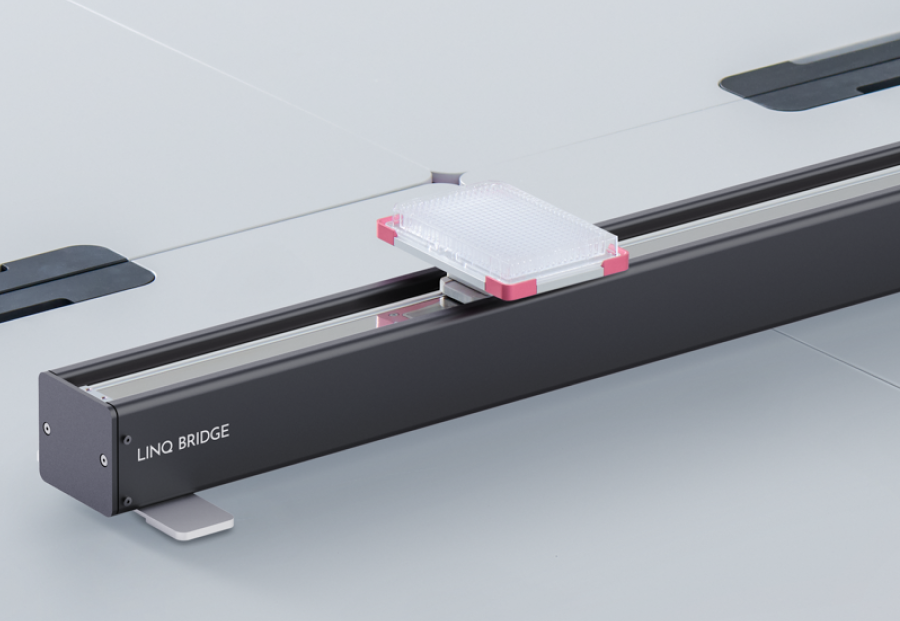

Bridge

Compact, low cost point-to-point transport

A cost-effective, space-efficient transport solution that connects sections of a workcell seamlessly. Ideal for labs prioritizing simplicity and compact setups, Bridge makes connecting two points of a workcell simple, enabling higher instrument density and more configuration options within limited space.

MagLev

Efficient, high-throughput plate transport

When high throughput, random access, and parallelized speed are essential, MagLev steps in. Built for labs needing rapid, multi-directional transport, MagLev is a magnetically levitating Planar Motor system that supports high-speed workflows. It ensures that even the most complex tasks are managed efficiently.

Get instant workflow visibility with bench-level feedback

LINQ Bench’s light system provides clear, immediate alerts on system status, ensuring errors are spotted and addressed without delay—keeping your lab running smoothly and efficiently.

Fast, reliable deployment with scalable support

The benefits of unified design - LINQ Bench's common hardware architecture is purpose-built for labs that demand scalability and efficiency. With a design optimized for consistency across setups, scaling up your operations becomes seamless, servicing is swift and straightforward, and support is more intuitive than ever.

Award Winning Innovation

Awarded the Red Dot for design excellence, LINQ Bench transforms labs with unmatched simplicity, power, and flexibility.

Book a meeting

Scale accurate data generation in your lab with intuitive workflow creation and data management.

Talk with our Automation experts for a personalised walkthrough of LINQ.