Empowering scientists by making automation a reality for every lab

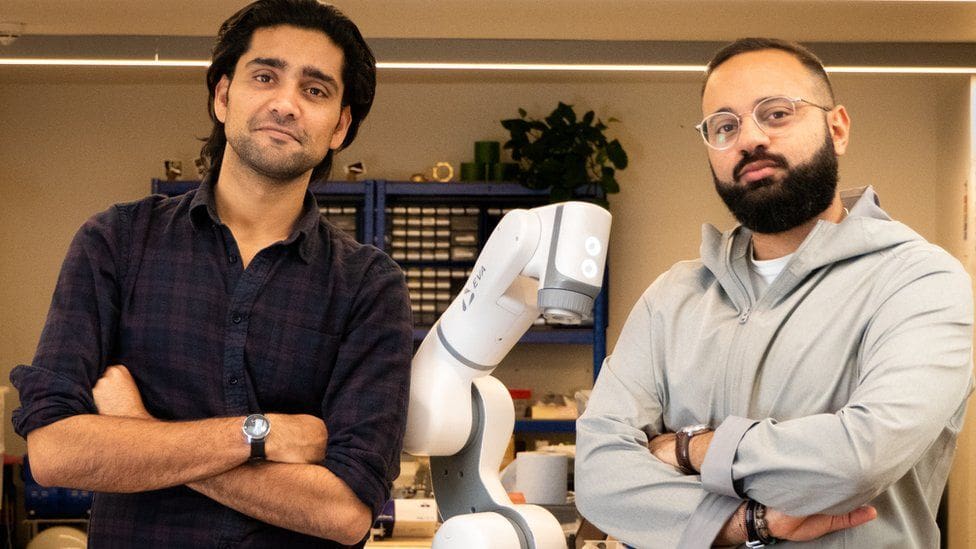

When two architects from Zaha Hadid’s research lab first approached robotics, their idea was to explore applications specific to architectural engineering.

But they soon discovered that modern automation wasn’t just unnecessarily complex – it was actively restricting innovation. And not just within their industry – in many others too. It was clear that robotic automation was a field where their combined experience in computational research and design could make a real difference.

Assembling a team of industry experts, Automata was founded with a clear aim: to enable new opportunities for innovation with automation.

Helping labs deliver results and medicines faster than ever

Automata’s focus narrowed on an industry where they felt their expertise could have the most impact: the life sciences.

Today, most lab automation tends to be defined by a series of very specialised benchtop instruments that are still reliant on human interaction. But Automata saw an opportunity for a new way of looking at automation in the life sciences: open, integrated automation.

That’s how we came to develop the world’s first fully automated lab bench, and its accompanying software. This enables labs to use staff and resources more effectively by ensuring total walkaway time and consistency, without compromising on valuable lab space.

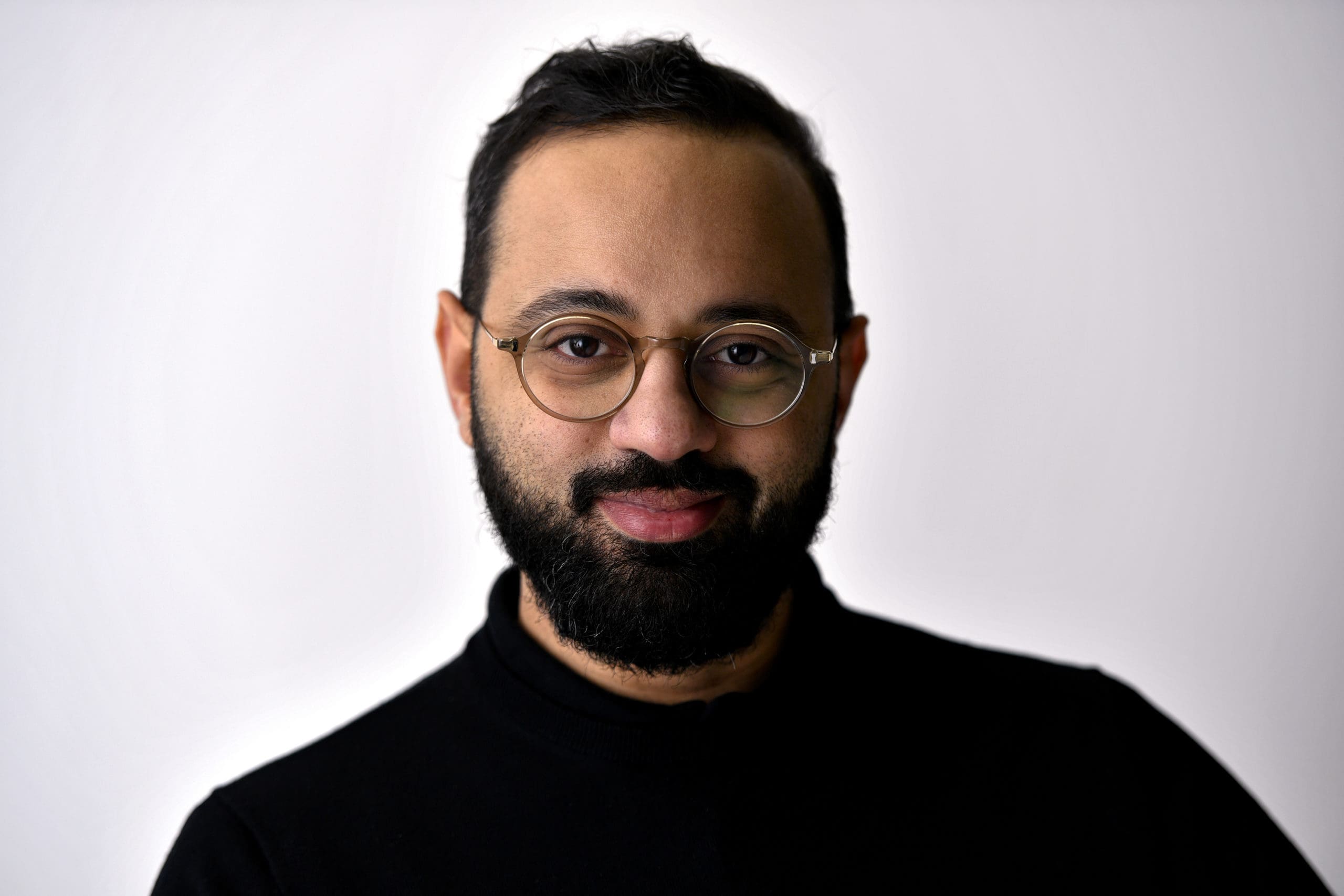

Mostafa ElSayed, CEO and Co-Founder

Mostafa ElSayed is the CEO and Co-Founder of Automata.

He has a Degree in Architecture from the American University of Sharjah; a Masters in Architecture and Urbanism; is a Fellow of the Royal Society for the Encouragement of Arts, Manufacturers and Commerce; and remains a course tutor in the Design Research Lab of the Architectural Association alongside his role as CEO of Automata.

After completing his Masters in 2014 Mostafa went on to join the world-renowned Zaha Hadid Architects, leaving the company as Lead Designer in the Computation and Design Group to found Automata with ZHA colleague Suryansh Chandra. (Chandra went on to launch new company, The Mind Distillery, in 2020 and remained a Director until resigning in 2021).

ElSayed and Chandra started Automata after seeing the need for automation and robotics to be applied in other sectors outside of architecture. Initially focused on manufacturing affordable robotic arms, Automata is now on a mission to transform how scientists work, delivering industry-changing automation solutions that lead the way in quality design and engineering.

Supported by a strong team of designers, engineers, scientists and leaders from a variety of life science backgrounds, Mostafa continues to drive Automata to the next level of success in his role as CEO.

Meet the leadership team

Thank you, EVA

EVA was the brainchild of former architects Mostafa ElSayed and Suryansh Chandra when, back in 2015, they founded Automata with the vision of making automation more accessible. With this mission, they assembled a team of industry experts, and EVA was born.

We’ve come a long way since then. And although we stopped producing EVA’s in 2022, we will always be indebted to – and thankful for – our history as the manufacturer of EVA.

In fact, many of the principles we established back at the company’s beginnings remain a huge part of who we are today; our approach to doing robotics differently, our passion for transforming industries with automation; and, of course, our team of amazing minds that are still creating innovative products to this day.

Automata is now proud to deploy our flagship product, LINQ; a lab automation platform enabling life science labs to fully automate their workflows.

Press releases and company news

Winner in the Product: Medicine/Health category Automata is pleased to announce that…

Read more LINQ wins iF Design Award

Health Services Laboratories unlocks faster turnaround times for NHS pathology services collaborating…

Read more HSL unlocks faster turnaround times for NHS pathology with Automata

Former lead investor, Joe Stringer joins Automata full-time bringing long track record…

Read more Joe Stringer joins Automata